NEWS&EVENTS

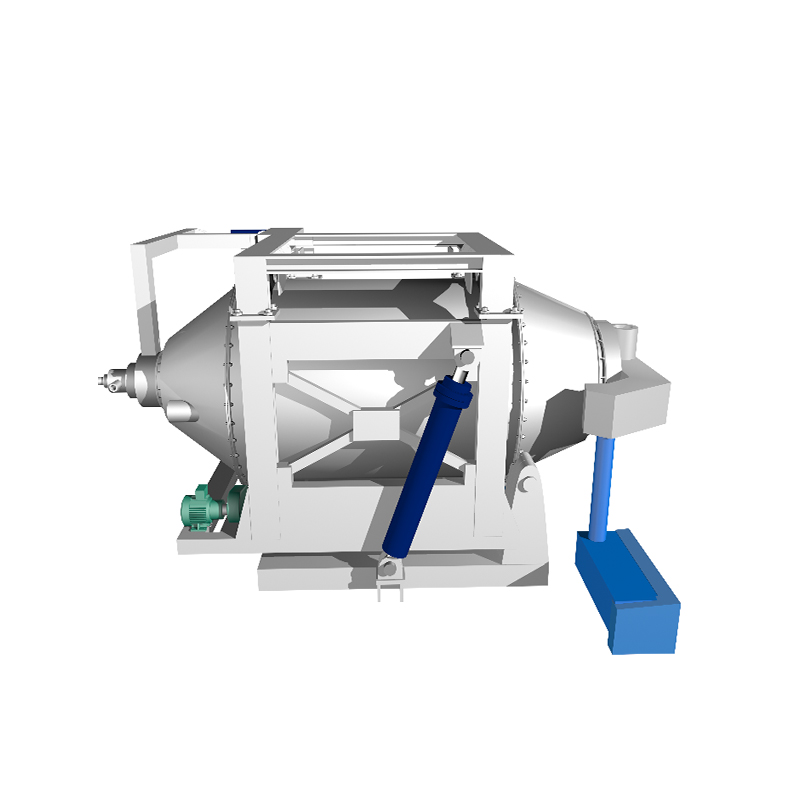

The factors that affect the fuel consumption of the rotary iron furnace include not only the furnace structure and burner performance; the heating system and the number of daily melting heats, but also the length of iron tapping time.

During the tapping of pure oxygen gas-fired rotary furnace, the temperature of molten iron drops to a certain extent, and the drop rate is about 50~70℃/h. If the tapping time is too long and repeated heating or heat preservation is required, the fuel consumption of the rotary furnace will increase significantly. In the most unfavorable case, the fuel consumption during tapping can even exceed the fuel consumption during smelting.

Therefore, the selection of rotary furnace capacity, ladle capacity, production organization and operating proficiency have a very important impact on the fuel consumption per ton of iron in pure oxygen gas rotary iron furnaces.

The above two articles comprehensively analyze the factors that affect the fuel consumption of rotary iron furnaces, and hope to be helpful in improving combustion efficiency.