NEWS&EVENTS

Home > News&Events > Company news > Rotary Furnaces 101: Efficiency, Applications & Innovation in Industrial Heating

Rotary Furnaces 101: Efficiency, Applications & Innovation in Industrial Heating

What is a Rotary Furnace?

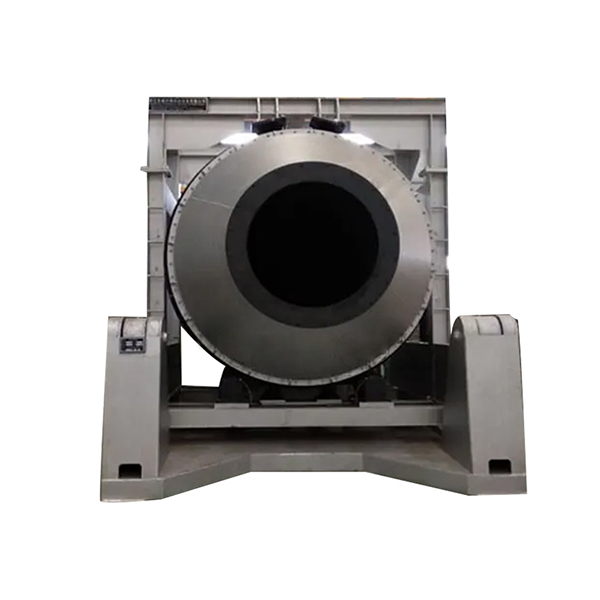

A rotary furnace is a cylindrical, inclined reactor that rotates to ensure uniform heating of bulk materials. Its design—featuring a refractory-lined chamber and adjustable rotation speed—enables precise thermal processing, making it critical in industries like metallurgy, chemical engineering, and waste recycling.

How It Works

Materials are fed into the furnace’s rotating drum, where direct or indirect heat (via flames, electric elements, or induction) triggers chemical/physical changes. Rotation ensures even exposure to heat, preventing hotspots and enhancing reaction efficiency.

Key Applications

Metallurgy: Smelts non-ferrous metals (e.g., lead, zinc) and recovers precious metals from scrap.

Chemical Processing: Calcines limestone, dries minerals, or produces activated carbon.

Waste Management: Incinerates hazardous waste, medical waste, or contaminated soil, meeting environmental standards.

Advantages for Industry

Energy Efficiency: Modern designs cut fuel use by 20% via heat recovery systems.

Versatility: Handles powders, granules, or lumpy materials without pre-treatment.

Durability: Refractory linings last 12+ months in continuous operation.

Maintenance & Optimization

Regular Inspections: Check for refractory cracks and drive-system wear.

Temperature Control: Use IoT sensors to monitor zones and avoid overheating.

Fuel Flexibility: Switch to biofuels or hydrogen to reduce emissions.

Future Trends

Digital Twins: Simulate furnace performance to predict failures and optimize cycles.

Circular Economy: Co-process waste-derived fuels (e.g., RDF) for sustainable operations.

AI Integration: Machine learning adjusts rotation/temperature in real time for peak efficiency.

Why Choose Anyutian?(Customize)

Our rotary furnaces combine cutting-edge insulation, smart automation, and 24/7 support to maximize uptime. Explore our [rotary furnace solutions] for your industry.