NEWS&EVENTS

Home > News&Events > Company news > Advantages of oxygen-enriched side-blowing rotary furnace in lead smelting

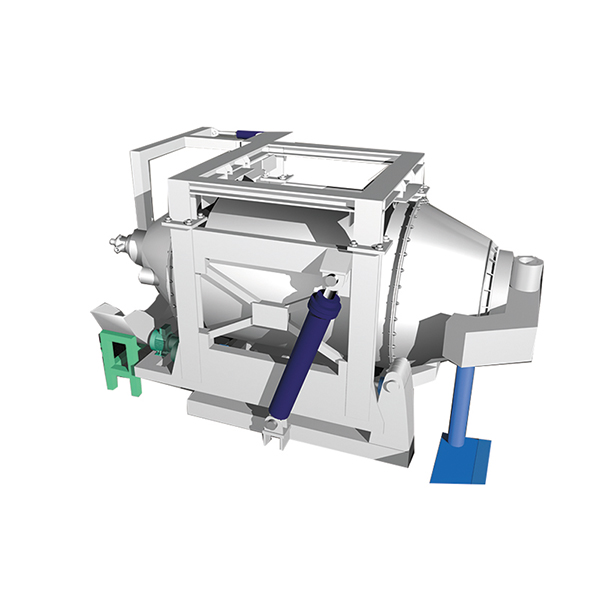

As a professional manufacturer in the field of rotary furnace production, we have been committed to exploring more efficient, environmentally friendly and cost-effective metal smelting technologies. Among many advanced technologies, oxygen-enriched side-blowing smelting technology has become the focus of our attention due to its significant advantages in many aspects.

1. Efficient mass transfer, heat transfer and enhanced reaction: Oxygen-enriched side-blowing technology blows oxygen-enriched air from the tuyere on both sides of the furnace body to form strong agitation, accelerate the mass transfer and heat transfer between the charge and oxygen and the reducing agent, make the charge melt quickly, and quickly oxidize raw materials such as lead sulfide concentrate to generate crude lead and slag, thereby improving smelting efficiency.

2. Strong adaptability of raw materials: It can process a variety of lead-containing materials and industrial solid wastes such as lead sulfide concentrate, lead oxide ore, lead slag, lead mud, etc., with low requirements for material particle size and moisture, no need for deep grinding or drying, simplifying the material preparation process and reducing costs.

3. Low energy consumption and high heat utilization rate: The high-temperature flue gas generated by smelting can be recycled through waste heat boilers for power generation or heating, and a variety of fuels such as natural gas, bituminous coal, and anthracite can be used to reduce operating costs.

4. Significant environmental benefits: The high concentration of sulfur dioxide in the flue gas is conducive to acid recovery and reduces sulfur oxide emissions; the furnace body is well sealed to reduce unorganized emissions; the materials entering the furnace do not need to be deeply ground, and the smoke rate is low.

5. High metal recovery rate: The lead recovery rate can reach more than 98%, and the lead content in the water-quenched slag is low, which is easy to handle and recycle.

6. Simple equipment structure and flexible operation: The furnace body is cooled by a copper water jacket, which has a long life and high operating rate. The production process can be intelligently controlled, reducing labor intensity and improving safety.

7. Short process flow and low investment: The pretreatment steps such as deep grinding and drying of materials are omitted, the construction speed is fast, the equipment configuration is simple, and there is no need for complex material preparation systems and expensive coke, and the investment cost is low.

8. Low-temperature smelting technology: Adding flux can reduce the temperature of lead smelting by pyrometallurgy, reduce the loss of refractory materials, and extend the life of the furnace body.

9. Comprehensive utilization of by-products: smoke can be returned to the batching system, and water-quenched slag can be used as raw material for cement production to achieve resource recycling.

Oxygen-enriched side-blowing smelting technology has brought new development opportunities to the metal smelting industry with its significant advantages such as high efficiency, environmental protection and low cost. As a rotary furnace manufacturer, we are willing to promote and apply this advanced technology to help the industry achieve green and efficient development and create a better future together.