NEWS&EVENTS

Home > News&Events > Company news > Customized solution for antimony rotary furnace: Accurately matching production needs

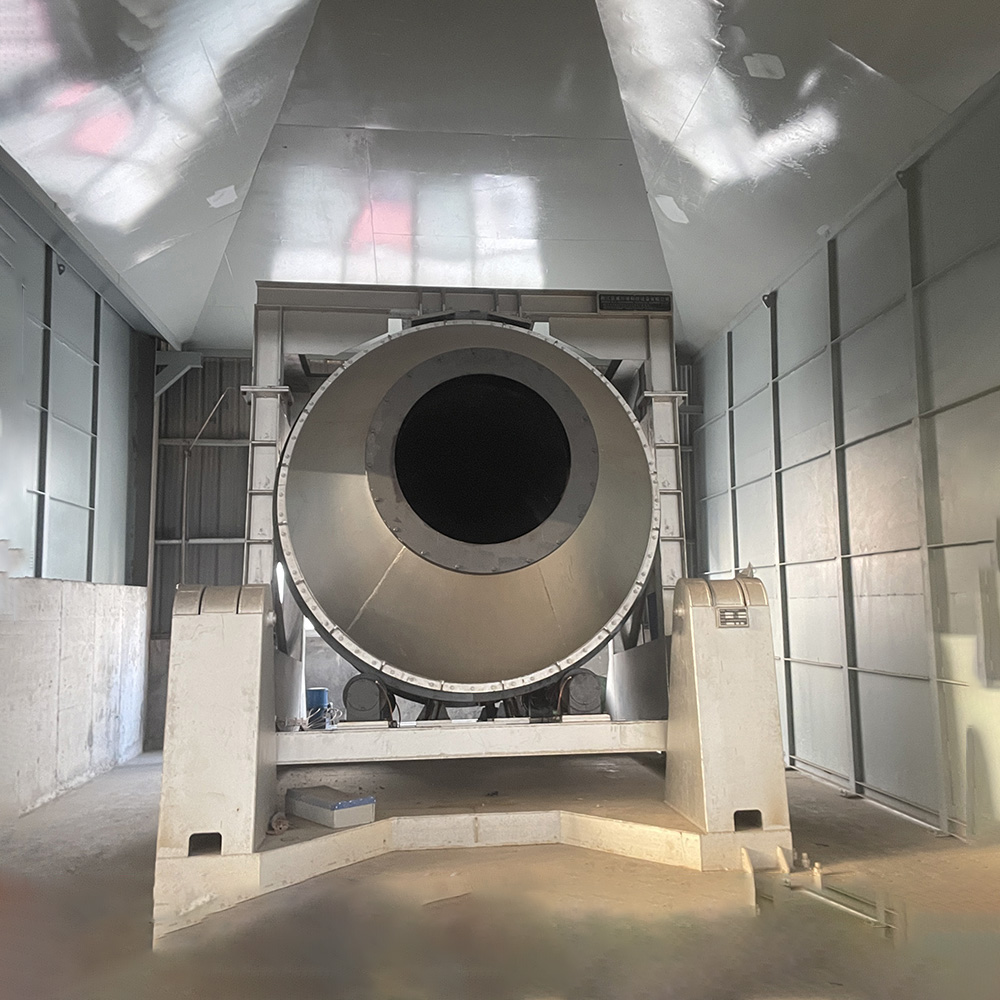

In the antimony smelting industry, the rotary furnace is the core equipment, and its performance is directly related to production efficiency and product quality. As a professional manufacturer, we are committed to providing customers with "precision customized" antimony rotary furnace solutions, and through technical optimization and innovation, we meet the diversified needs of different scales, raw material characteristics and environmental protection requirements.

1. The raw materials for antimony smelting are complex and diverse, including antimony sulfide ore, oxide ore, waste slag and secondary resources. The design of the rotary furnace needs to adjust the structural parameters according to the characteristics of the raw materials:

1. Furnace size and speed: For low-grade ore or raw materials with high impurities, the reaction time can be extended by lengthening the furnace body and optimizing the speed (such as 0.5-1.5 rpm) to improve the metal recovery rate.

2. Refractory material selection: Use high-aluminum or magnesium-chromium lining to withstand high temperature (1200-1400℃) and acidic/alkaline slag erosion, and extend the life of the furnace.

3. Thermal system optimization: Combined with the fuel type (natural gas, coal gas or electric heating), design multiple temperature control zones to ensure the stability of the volatilization and reduction reaction of antimony oxide powder.

2. Under the background of stricter environmental protection requirements, rotary kilns need to achieve "ultra-low emissions" and resource recycling:

1. Waste gas treatment system: configure high-efficiency dust collection (such as bag dust removal) and desulfurization equipment (double alkali method or activated carbon adsorption) to ensure that the sulfur dioxide concentration is ≤50mg/Nm³ and the dust emission is ≤10mg/Nm³, which meets the emission requirements.

2. Waste heat recovery: use the waste heat of flue gas to preheat raw materials or generate electricity, reduce energy consumption by 20%-30%, and help customers achieve carbon neutrality goals.

3. Solid waste resource utilization: for antimony-containing waste slag, design a supporting smelting system to achieve comprehensive recovery of valuable metals such as antimony and gold.

3. Realize real-time monitoring and adjustment of process parameters through digital technology:

1. Automated batching system: automatically adjust the proportion according to the raw material composition, reduce manual errors, and ensure that the purity of antimony oxygen powder is ≥98%.

2. Intelligent temperature control module: combine infrared temperature measurement and AI algorithm to dynamically adjust the heating power to avoid local overburning or insufficient reaction.

3. Remote operation and maintenance platform: supports equipment status diagnosis and fault warning, reduces downtime risk, and improves operation and maintenance efficiency.

The customized design of the antimony rotary furnace requires deep integration of process requirements, environmental protection standards and intelligent technology. Our solution is centered on "precise matching" and helps customers achieve efficient, low-carbon and high-yield antimony smelting production through modular design and flexible configuration. In the future, we will continue to explore the innovative application of rotary furnaces in complex ore processing, short-process smelting and other fields to promote the green transformation of the industry.