NEWS&EVENTS

Home > News&Events > Company news > Why antimony electrolytic cells need to be designed with corrosion-resistant materials

Antimony electrolytic cells need to be designed as corrosion-resistant materials, mainly based on the following core reasons:

The working environment of antimony electrolytic cells is full of corrosive threats. On the one hand, there is strong acid/alkali erosion, such as concentrated sulfuric acid, concentrated hydrochloric acid or high-concentration hydrofluoric acid environment. Hydrofluoric acid concentration exceeding 15% will seriously corrode the surface of the antimony electrode, and even cause it to dissolve and release toxic antimony compounds. On the other hand, there are high temperature and high pressure conditions. During high-temperature electrolysis, the antimony oxidation reaction is intensified and the material stability decreases. For example, in a sulfide corrosion environment above 240°C, the antimony electrode is easy to react with hydrogen to generate methane bubbles, resulting in intergranular fracture.

Although antimony materials are inherently corrosion-resistant, they are risky under certain conditions. One is selective corrosion, which is easily oxidized in strong oxidizing acids. A chemical plant once mistakenly connected 40% hydrofluoric acid to the antimony electrode electrolytic cell, causing the electrode to dissolve and causing a safety accident. The second is the risk of galvanic corrosion. Antimony contacts other metals to form a primary cell in the electrolyte, accelerating the corrosion of low-potential metals.

Corrosion will directly lead to reduced efficiency of the electrolytic cell and safety hazards. Structurally, corrosion causes leakage of the tank body and seal failure, leading to alkali leakage, gas leakage and other problems. After long-term operation, the tank needs to be stopped for maintenance. In terms of electrolysis efficiency, corrosion products contaminate the electrolyte, increase the solution resistance, and cause the tank voltage to rise and the current efficiency to decrease. The life of the electrode will also be shortened. Frequent corrosion requires replacement of the electrode, which increases production costs.

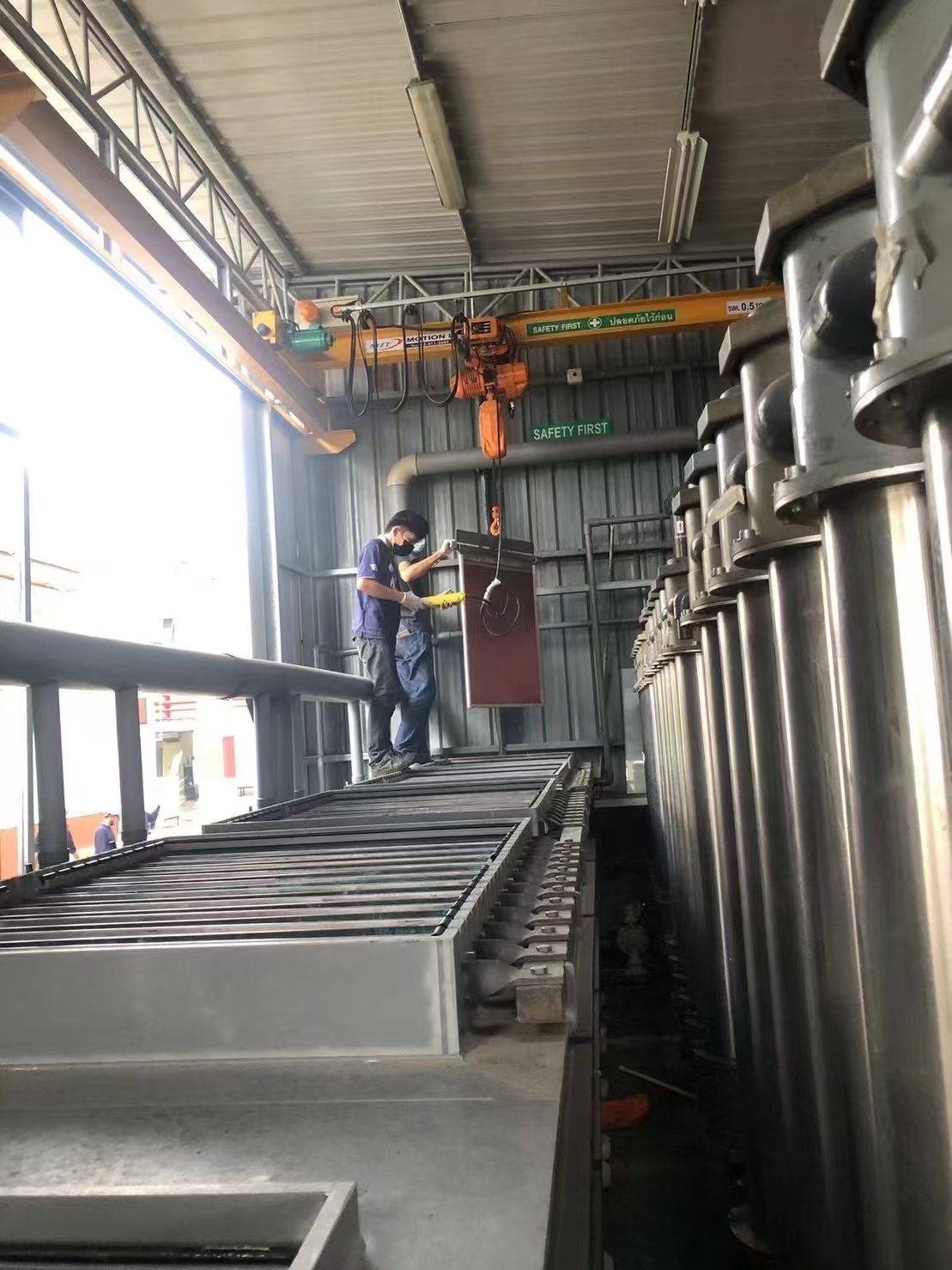

The use of corrosion-resistant materials can significantly reduce long-term costs and improve safety. Traditional antimony electrolytic cells are gradually replaced by titanium alloys, stainless steel or composite materials. For example, titanium plates are widely used in high-demand electrolytic processes due to their light weight, high strength and excellent corrosion resistance. Although the initial cost is high, the service life is long, which can reduce the number of shutdowns for maintenance, prevent the leakage of toxic substances, and avoid environmental pollution.

At present, the material selection of electrolytic cells tends to be diversified. Composite materials such as lead-antimony alloy plates, PVC and fiberglass are used. PVC materials are often used in ion membrane electrolytic cells. Surface modification technology is also developing, such as platinum plating or coating catalytic active materials on the surface of the electrode to enhance corrosion resistance and electrolysis efficiency. In the future, new composite materials and surface modification technologies will drive the electrolyzers to develop in the direction of high efficiency, longevity and environmental protection.