NEWS&EVENTS

Home > News&Events > Company news > How to improve the volatilization efficiency by raw material pretreatment in rotary furnace antimony smelting

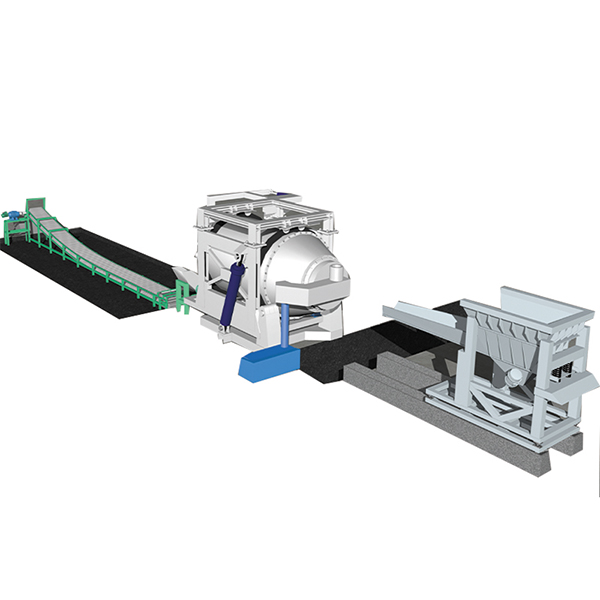

In the process of rotary furnace antimony smelting, raw material pretreatment is the key link to improve the volatilization efficiency. It can create favorable conditions for the subsequent oxidation reaction, thereby improving the efficiency and quality of the entire antimony smelting process.

1. Crushing and screening link

Before entering the rotary furnace, the antimony ore needs to be processed by crushing equipment to crush its particle size to ≤3mm. This operation is of great significance because the specific surface area of the ore will increase significantly after the particle size is reduced. The increase in specific surface area means that the contact area between the ore and the reaction gas increases, and the oxidation reaction can be carried out more quickly and fully, thereby greatly shortening the time required for the oxidation reaction and laying the foundation for improving the volatilization efficiency.

2. Ore blending adjustment

Due to the difference in the grade of antimony ore from different origins, by reasonably mixing high-grade and low-grade ores, the antimony content of the material entering the furnace can be accurately controlled to stabilize it within the appropriate range of 12% to 18%. If the antimony content fluctuates too much, local overheating may occur in the furnace, which will not only affect the volatilization efficiency, but also may cause damage to the equipment. Therefore, scientific ore blending adjustment is essential to ensure the stability and volatilization efficiency of the antimony smelting process.

3. Pre-oxidation roasting link

For antimony ore with a high sulfur content, it is necessary to pre-oxidize and roast at a temperature of 500-600°C before entering the rotary kiln. This step can effectively reduce the sulfur content in the ore and reduce the burden of sulfur decomposition in the rotary kiln. If pre-oxidation roasting is not performed, a large amount of harmful gas will be produced when sulfur decomposes in the rotary kiln, which will also affect the oxidation reaction and reduce the volatilization efficiency. Through pre-oxidation roasting, the reaction environment in the rotary kiln can be ensured to be more stable, thereby improving the volatilization efficiency and ensuring the smooth progress of the antimony smelting process.