NEWS&EVENTS

Home > News&Events > Company news > How to treat high arsenic antimony ore by slurry electrolysis process

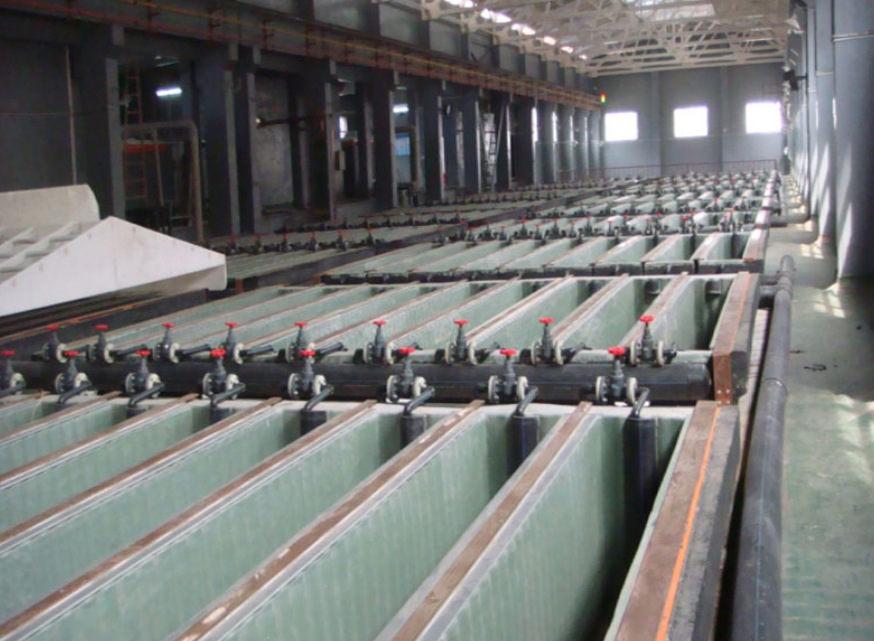

When the slurry electrolysis process is used to treat high-arsenic antimony ore, the presence of arsenic will have an adverse effect on the entire process. Therefore, a series of measures need to be taken to effectively control the impact of arsenic and ensure the smooth extraction of antimony.

The first is the anodic oxidation process. During the slurry electrolysis process, the arsenic in the high-arsenic antimony ore will undergo an oxidation reaction and be oxidized to As³⁺ or As⁵⁺. Among them, some arsenic will enter the anode mud. After this process, the enrichment of arsenic in the anode mud can reach 13-14 times, which to a certain extent achieves the initial separation and enrichment of arsenic.

The second is electrolyte purification. As the electrolysis process continues, the arsenic content in the electrolyte will gradually increase. In order to maintain the quality of the electrolyte and the stability of the process, the electrolyte needs to be extracted regularly for treatment. Chemical precipitation or ion exchange is usually used to remove arsenic from the electrolyte, thereby reducing the interference of arsenic on subsequent electrolysis reactions.

The third is cathodic protection measures. During the electrolysis process, the current density and the composition of the electrolyte must be strictly controlled. By precisely controlling these parameters, the co-precipitation of arsenic and antimony on the cathode can be avoided, ensuring the purity and extraction efficiency of antimony.

The last step is the pyrolysis separation step. The electrolytic slag produced during the electrolysis process contains a certain amount of arsenic. Through pyrolysis treatment, the arsenic is converted into volatile As₂O₃ or AsCl₃. These volatile substances are separated from the solid slag at high temperature, thereby achieving further removal of arsenic.

Through a series of measures such as anodic oxidation, electrolyte purification, cathodic protection and pyrolysis separation, the slurry electrolysis process can effectively treat high-arsenic antimony ores, while controlling the impact of arsenic, achieving efficient extraction of antimony.