NEWS&EVENTS

Home > News&Events > Company news > Process for producing antimony ingot and antimony trioxide from antimony ore

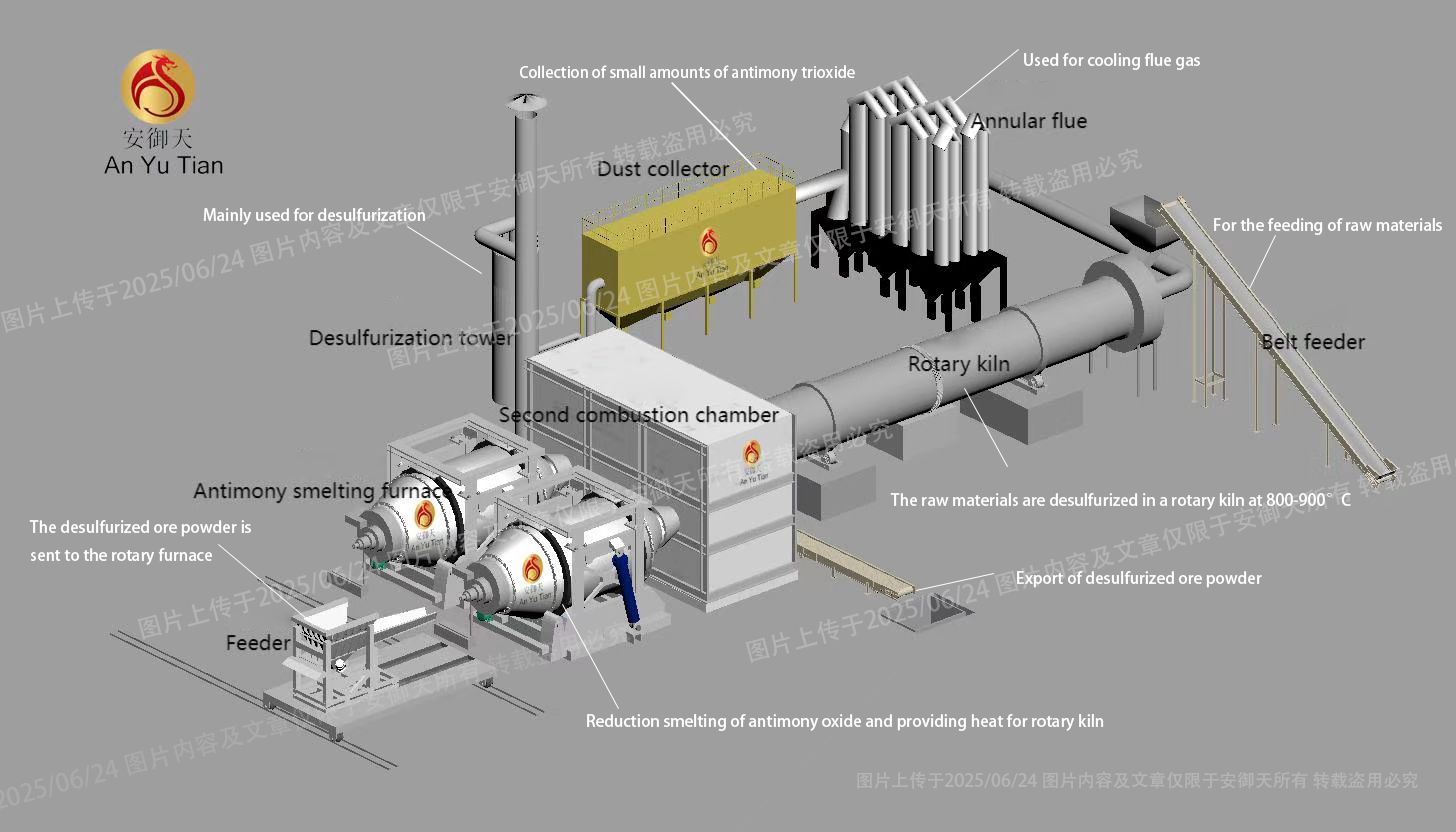

In the processing of antimony ore, the rotary kiln plays a pivotal role. The entire process starts with a belt feeder, which smoothly and continuously transports the raw ore - antimony ore to the rotary kiln. In the rotary kiln, the ore is roasted at a high temperature of 800-900℃, which achieves effective desulfurization. The desulfurized ore powder is discharged from the discharge port and then accurately fed to the next link - the rotary kiln by the feeder.

The rotary kiln is one of the core equipment in the entire processing process. Here, the ore powder is reduced and smelted at high temperature to produce crude antimony metal. Not only that, the rotary kiln also undertakes the key task of providing heat for the rotary kiln. This energy recycling improves the efficiency of the entire process and reduces energy consumption.

The high-temperature flue gas generated by smelting then enters the annular flue for preliminary cooling, and then passes through the dust collector, where the small amount of valuable antimony trioxide contained in it is effectively recovered. Finally, the flue gas enters the desulfurization tower to complete the final desulfurization and purification treatment to ensure that environmental protection emission requirements are met.

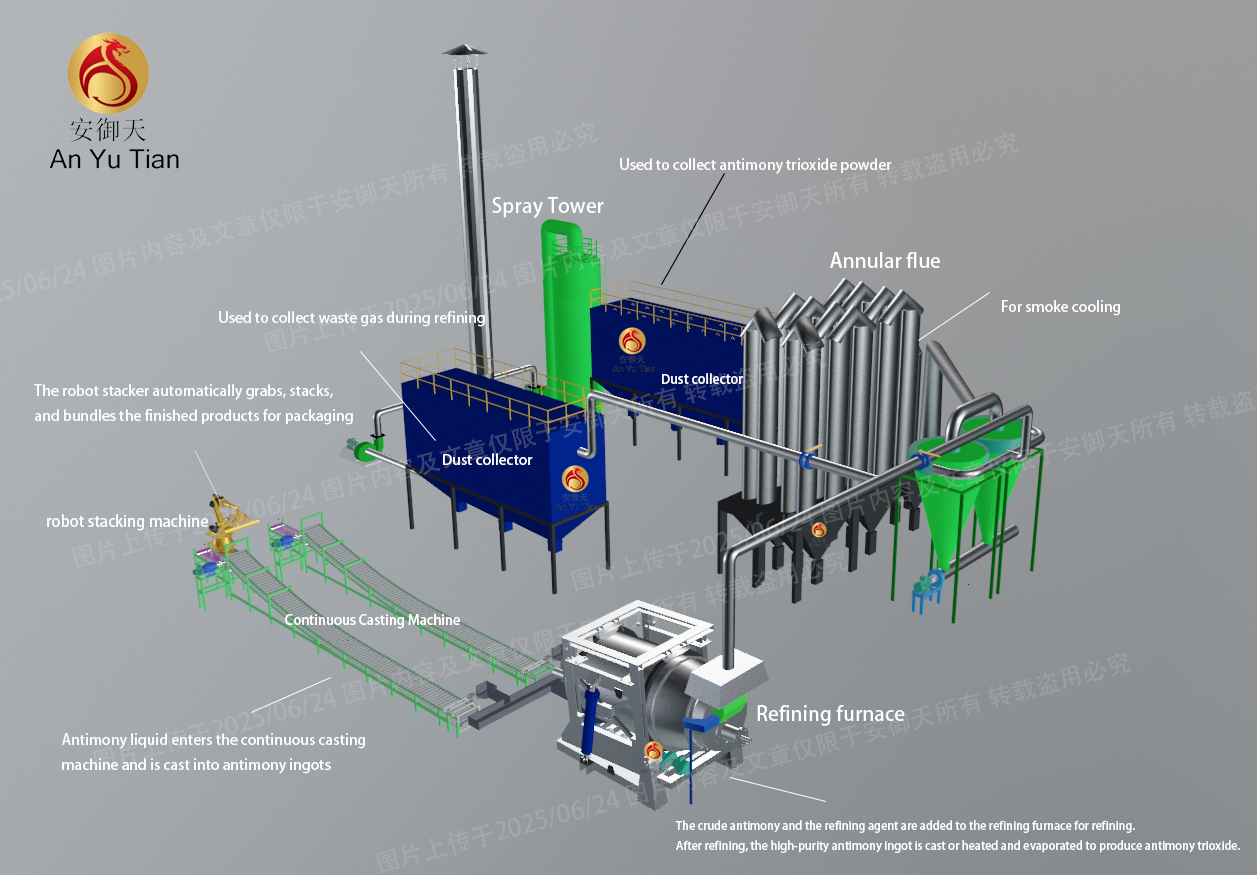

If you want to obtain refined antimony or antimony trioxide, you need to go through a series of subsequent processes. In the high-temperature reduction stage, crude antimony and refining agents are added to the refining furnace for refining to obtain pure antimony liquid. If you want to obtain antimony ingots, the antimony liquid enters the continuous casting machine. The hot antimony ingots after forming are automatically grabbed, stacked, and bundled by the manipulator stacking machine to complete the finished product packaging. If you want to obtain antimony oxide powder, the antimony liquid is oxidized in the refining furnace (oxidation furnace) to obtain antimony trioxide. At high temperature, antimony trioxide volatilizes and enters the dust removal system, and the antimony trioxide powder is collected in the dust collector.

From antimony ore to the final product, the rotary furnace runs through the whole process. It not only plays a key role in the smelting link, but also ensures the efficient and environmentally friendly operation of the entire process through the coordinated work with other equipment. It is the existence of the core equipment of the rotary furnace that allows antimony ore to be converted into various valuable products, providing a solid material foundation for the development of related industries.