NEWS&EVENTS

Home > News&Events > Company news > What are the advantages of rotary furnace in antimony smelting compared with reverberatory furnace?

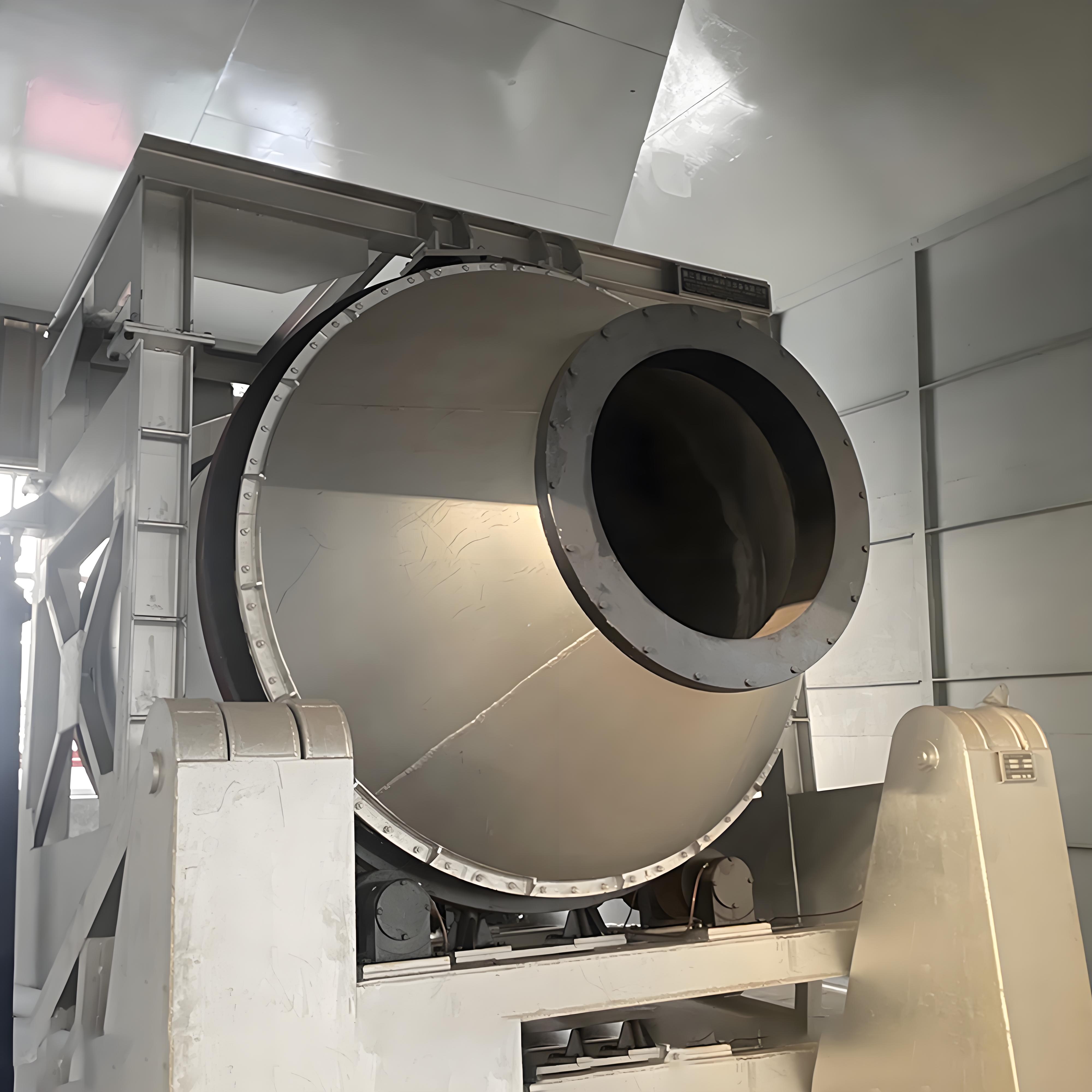

In the modern antimony smelting industry, rotary furnaces and reverberatory furnaces are two common types of equipment, and there are significant differences in their process performance. With its unique dynamic mixing mechanism, continuous production capacity and efficient flue gas waste heat recovery system, the rotary furnace has shown obvious advantages in reaction efficiency, production capacity scale and energy utilization, and has become the mainstream choice in the current antimony smelting field. Specifically:

1. Even material mixing and high reaction efficiency

The rotary furnace uses rotational motion to make the material tumble continuously in the furnace to achieve dynamic mixing, ensure full contact between the reactants, reduce local reaction unevenness, and significantly improve the reaction rate and conversion efficiency. However, the reverberatory furnace has stationary materials, poor mixing effect, and is prone to incomplete reaction.

2. Strong continuous production capacity and large processing capacity

The rotary furnace supports continuous feeding and discharging, which can realize large-scale industrial production. The processing capacity of a single furnace far exceeds the batch operation mode of the reverberatory furnace, which is suitable for high-capacity demand scenarios. The reverberatory furnace needs to be frequently stopped for loading and unloading, which limits production efficiency.

3. Flue gas waste heat is easy to recover, and energy consumption is low

The flue gas flow path of the rotary furnace is concentrated and stable, which is convenient for matching waste heat recovery systems (such as waste heat boilers, air preheaters), and can efficiently use flue gas heat to preheat raw materials or generate electricity, reducing comprehensive energy consumption. The flue gas of the reverberatory furnace is dispersed, and waste heat recovery is difficult, and the energy utilization rate is low.

Summary: Through the three characteristics of dynamic mixing, continuous production, and efficient use of waste heat, the rotary furnace is significantly superior to the traditional reverberatory furnace in terms of efficiency, production capacity and energy consumption, and has become the mainstream equipment for modern antimony smelting.