NEWS&EVENTS

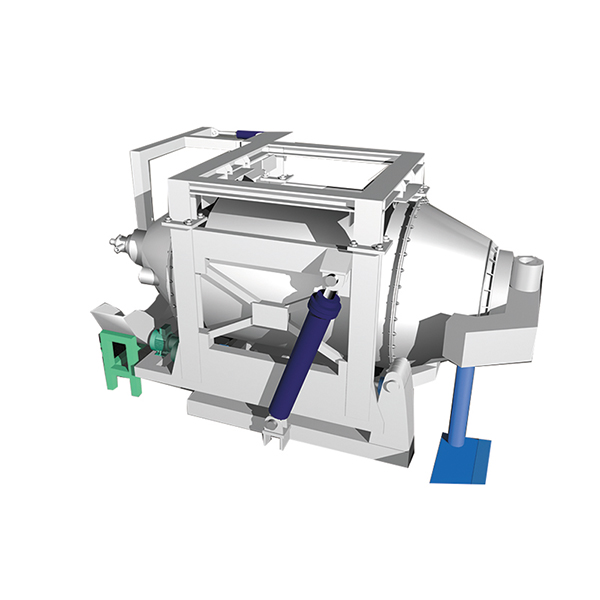

Home > News&Events > Company news > High-efficiency and environmentally friendly antimony ore smelting equipment rotary furnace

Efficient and environmentally friendly rotary furnace equipment is crucial in the process of producing antimony trioxide from antimony ore by pyrometallurgical smelting. Its high efficiency is reflected in two aspects: one is that it can quickly process antimony ore, and the other is that it can accurately control roasting parameters such as temperature gradient, gas flow rate and redox atmosphere, ensuring that antimony elements are converted into antimony trioxide in the optimal path, improving production efficiency and product quality consistency, reducing by-products, and providing pure raw materials for refining.

In terms of environmental protection, modern rotary furnace technology integrates advanced flue gas purification systems, which is a significant difference from traditional smelting methods. The system has a multi-stage dust removal device, and the dust collector is combined with a wet scrubber to efficiently capture and remove harmful substances such as particulate matter and sulfur dioxide in the flue gas, so that the exhaust flue gas meets strict environmental protection standards. Some advanced rotary furnaces are also equipped with waste heat recovery devices to convert high-temperature flue gas waste heat into steam or electricity, realize energy recycling, reduce energy consumption and carbon emissions, and embody the concept of green smelting.

In addition, the design of the equipment focuses on easy operation and simple maintenance. The modular structure makes installation, commissioning and subsequent maintenance efficient and fast, reduces downtime and improves overall production efficiency. The intelligent monitoring system can monitor the operating status of the equipment in real time, warn of potential failures in advance, and ensure production safety. This design concept reduces operating costs and enhances the company's market competitiveness.

In short, the efficient and environmentally friendly rotary furnace equipment has become a leader in the field of pyrometallurgical smelting of antimony ore to produce antimony trioxide with its excellent processing capacity, fine operation control, advanced flue gas purification technology and intelligent design concept, promoting the green transformation of the antimony smelting industry and helping the sustainable utilization of global antimony resources.