NEWS&EVENTS

Home > News&Events > Company news > Environmental Protection Measures in the Production of Antimony Trioxide

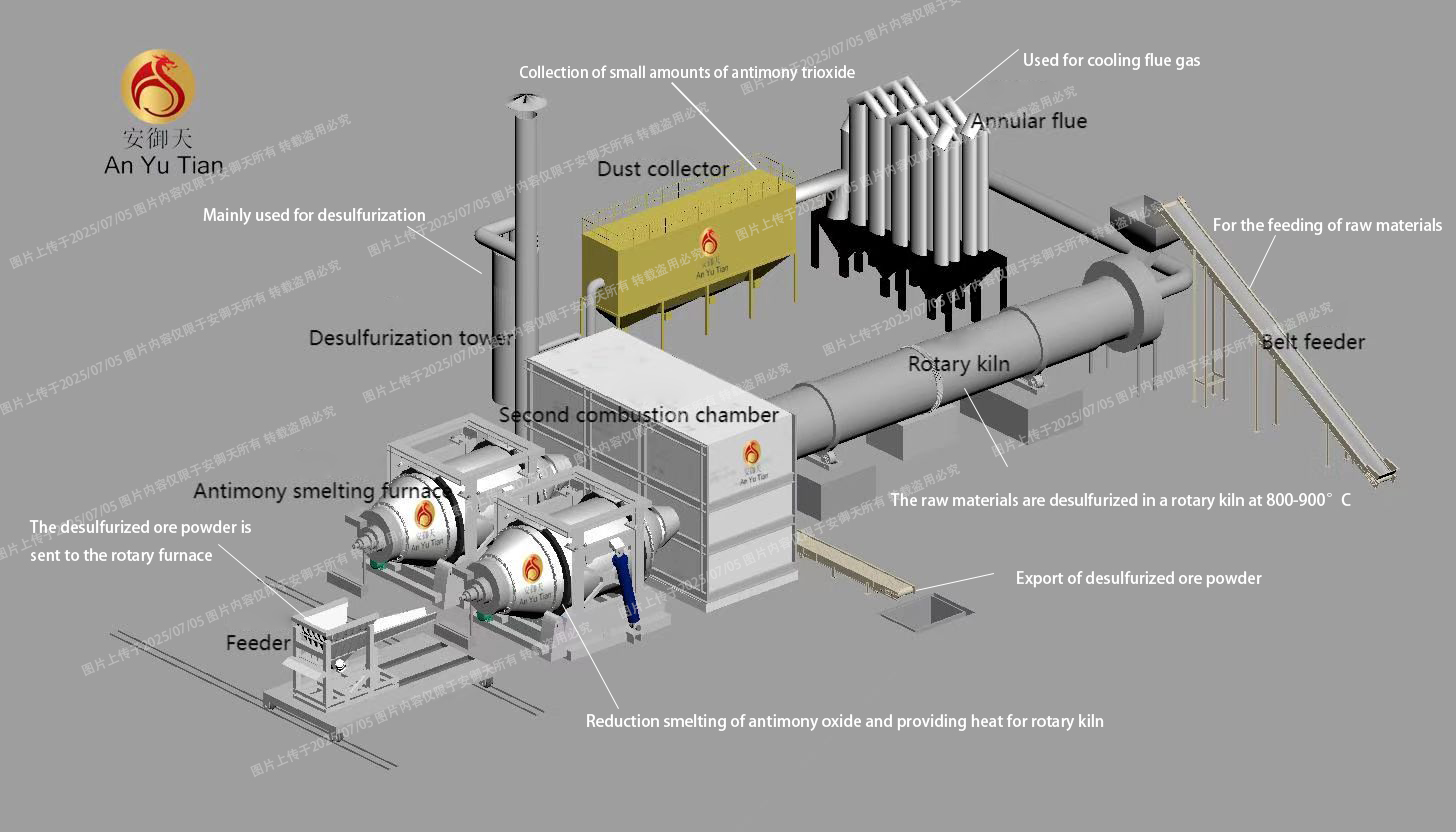

A series of strict and efficient environmental protection measures are taken in the production of antimony trioxide to ensure that the standards are met. During the operation of the oxidation furnace, the temperature and reaction conditions are precisely controlled to reduce the generation of harmful gases such as nitrogen oxides from the source. A pretreatment device is added to the exhaust port to remove some pollutants in advance by chemical adsorption.

When antimony trioxide volatilizes into the dust removal system, an advanced pulse bag dust collector is used. It has a large filtration area and high efficiency. It can capture fine particles and dust impurities, making the concentration of flue gas particles far lower than the standard. The bag material is resistant to high temperature and corrosion, ensuring stable effect.

The desulfurization tower adopts a double alkali desulfurization process. First, sulfur dioxide is absorbed by sodium hydroxide solution to generate sodium sulfite, and then regenerated with lime milk. The sodium hydroxide solution can be circulated, and the desulfurization efficiency is more than 95%. The desulfurization slag can be comprehensively utilized. The multi-layer spray device in the tower allows the desulfurization liquid to fully contact the flue gas to improve the desulfurization effect.

The layout of the production workshop is scientific and reasonable, with dust-producing exhaust equipment centrally arranged, a closed operating space, and a negative pressure exhaust system to collect exhaust gas for subsequent treatment.

The company has established a sound environmental monitoring system, installed online monitoring equipment at key links, uploaded data to the regulatory authorities in real time, and regularly maintained and repaired environmental equipment. Through these measures, antimony trioxide production has achieved clean, environmentally friendly, and sustainable development.