NEWS&EVENTS

Rotary furnace smelting of low-grade tin ore (generally ore with a tin content of less than 1%-3%) is a highly efficient method, particularly suitable for complex, difficult-to-process, or fine-grained ores. The rotary furnace (also known as a rotary kiln or rotary smelting furnace) plays a vital role in the processing of low-grade tin ore due to its excellent material mixing, efficient heat and mass transfer, and wide adaptability. The following are key technologies and process highlights for rotary furnace smelting of low-grade tin ore:

1. Raw Material Preparation:

Ore Concentration: Smelting low-grade ore requires pre-concentration (gravity separation, flotation, etc.) to raise the tin grade to an economical smelting level (e.g., 5%-20% or higher) and remove gangue minerals to reduce costs.

Batching: Tin concentrate, flux (such as limestone, used for slag formation, slag shape adjustment, and melting point viscosity reduction), and reducing agent (pulverized coal or coke) are mixed in precise proportions. The proportions affect reduction efficiency, among other factors. Pelletizing/Agglomeration: The mixed material is formed into pellets or briquettes to improve the charge's air permeability.

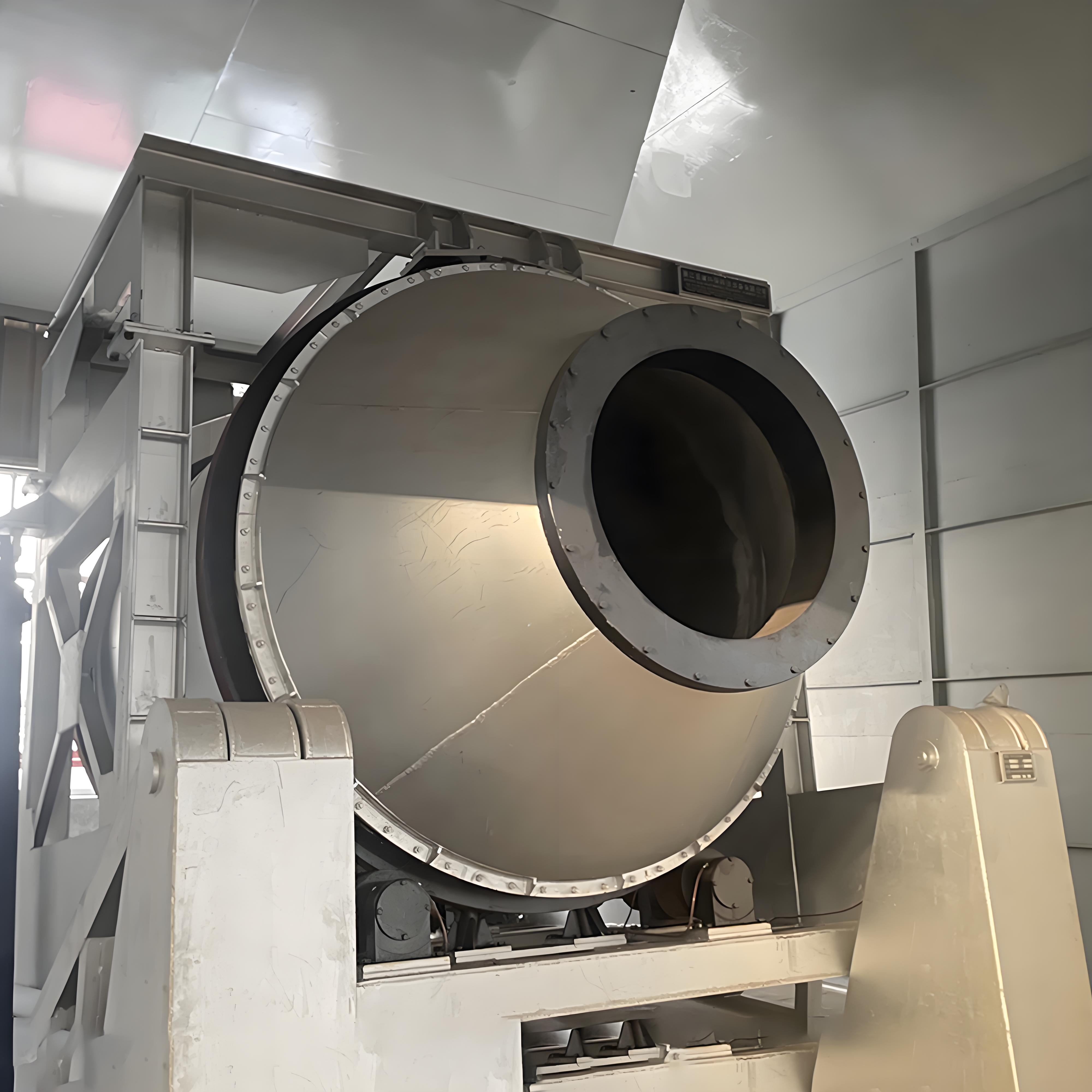

II. Rotary Kiln Structure and Principle:

Furnace: A long cylindrical steel body lined with refractory material, tilted (1-5 degrees), supported by rollers, and capable of low-speed rotation (0.5-5 rpm).

Heating Method: External burners directly heat the furnace walls, radiating and conducting heat to the charge. Direct fuel injection or oxygen-enriched combustion designs are also available.

Material Movement: The furnace body rotates, tumbling, mixing, and moving the charge toward the furnace tail, ensuring uniform heating and adequate gas-solid contact, facilitating the reduction reaction.

III. Smelting Process (Reduction Smelting):

Drying and Preheating Stage: The charge is added at the furnace head and initially dried, dehydrated, and preheated.

Reduction Stage: The temperature rises to 1100°C-1350°C. In a reducing atmosphere, tin oxide (primarily SnO₂) is reduced to metallic tin. The main reactions are gaseous and solid-state reduction. Slag Formation and Separation: Gangue minerals react with flux to form a low-melting-point, highly fluid slag. Liquid tin and slag separate by gravity in the molten pool due to density differences.

Furnace Atmosphere Control: Maintaining an appropriate reducing atmosphere (CO/CO₂ ratio) is crucial for tin reduction efficiency and preventing over-reduction of impurity metals. Over-reduction can form hardened tin and reduce direct recovery.

IV. Product Discharge and Treatment:

Crude Tin: A siphon or tin discharge port is located at the furnace tail end to periodically or continuously discharge molten crude tin. Tin containing impurities requires further refining.

Slag: A slag discharge port is located above the furnace tail end for continuous or intermittent discharge. Slag from low-grade ore smelting contains a high tin content (1%-10% Sn) and requires further treatment to improve overall recovery.

Flue Gas: Smelting generates high-temperature flue gas containing dust, SO₂ (when the raw materials contain sulfur), CO, and CO₂. Tin dust is recovered by a dust collection system (returned to the batching), and desulfurization and other environmentally friendly treatments are performed before discharge to meet emission standards. Excess heat is recovered through a waste heat boiler for steam recovery.