NEWS&EVENTS

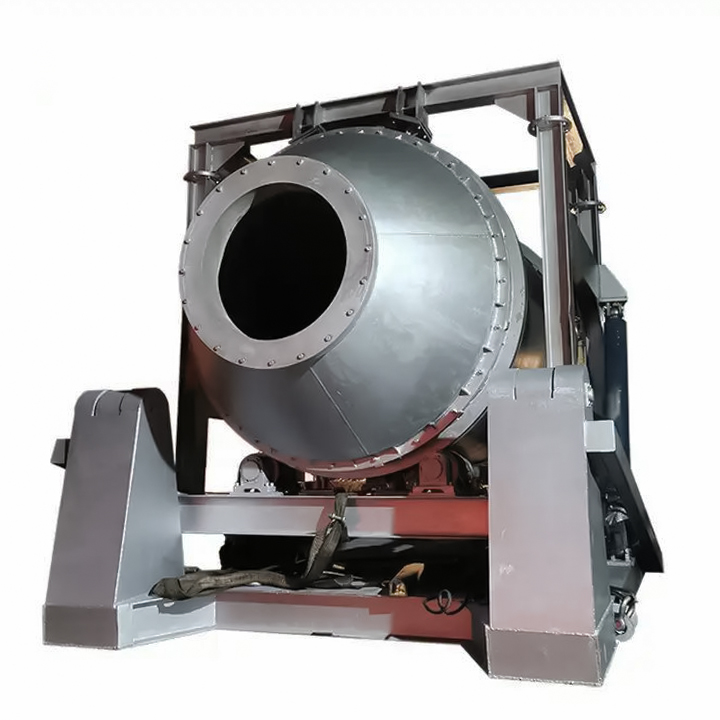

The rotary furnace is a key piece of equipment commonly used in mineral roasting in the metallurgical industry. Its operating parameters significantly impact production process stability, product quality, and energy consumption. Rotational speed, a key control parameter, directly determines the movement of materials within the furnace, reaction time, and mass and heat transfer efficiency. In the oxidation roasting of stibnite (Sb₂S₃), proper control of rotational speed is particularly crucial, directly impacting desulfurization efficiency, product composition, and overall economic viability.

Too slow a rotation speed slows the axial movement of the material and prolongs the residence time. While this can accelerate the reaction, excessively prolonged residence time can further oxidize the generated Sb₂O₃ into Sb₂O₄, which is difficult to reduce. This reduces the recovery rate of the target product and increases the difficulty and cost of subsequent reduction. Furthermore, this reduces the equipment's processing capacity, reduces production capacity, and increases production costs.

Excessive rotation speeds prevent the material from remaining in the furnace for a sufficient period of time, leading to its discharge before the reaction is fully complete. The desulfurization reaction in stibnite ore takes time, and unreacted sulfur remains in the roasted sand, affecting the purity of the antimony product. This increases the burden on subsequent smelting processes and the amount of sulfur dioxide generated in the flue gas, further straining the environment. Furthermore, high-speed rotation causes the material in the furnace to churn violently, making powdered material easily carried into the flue gas system by the airflow. This increases the load on dust removal equipment, causes metal dust loss, and reduces resource utilization.

To achieve efficient and stable roasting, the rotation speed must be comprehensively adjusted. The optimal rotation speed range should be determined through experiments based on the physical characteristics (particle size distribution, moisture content) and chemical properties (sulfur content, reactivity) of the stibnite ore, aligning the material residence time with the reaction requirements. For fine-grained, highly reactive ores, the rotation speed can be increased appropriately, while for coarse-grained or recalcitrant ores, the rotation speed can be reduced. Furthermore, parameters such as furnace inclination, temperature distribution, and air supply conditions should be optimized in a coordinated manner.

The rotation speed of the rotary kiln affects the reaction path and economic benefits of stibnite roasting. Scientifically controlling the rotation speed can balance production capacity, quality and energy consumption. This concept is also applicable to the roasting of other sulfide minerals, highlighting the importance of coordinated optimization of "time-space-reaction".