NEWS&EVENTS

Home > News&Events > Company news > The main advantages of rotary furnace in tin concentrate smelting

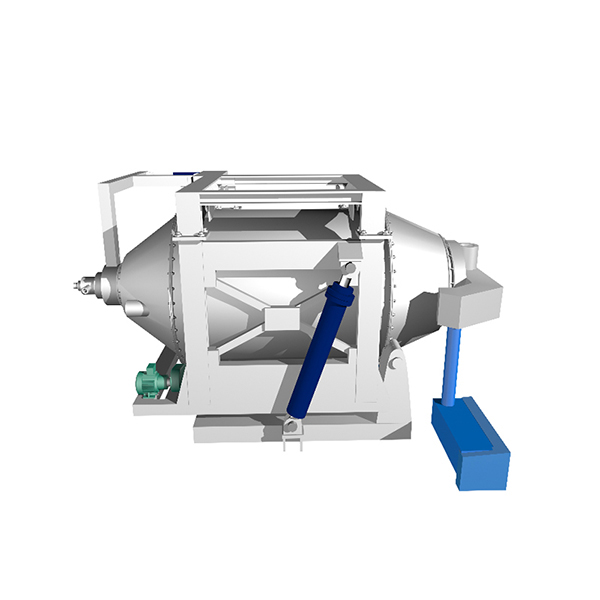

In the smelting process of tin concentrate, the rotary furnace (also known as a rotary short kiln), as a highly efficient reaction equipment, offers significant advantages over traditional reverberatory furnaces in many aspects. These advantages primarily lie in heat transfer efficiency, smelting intensity, material adaptability, and automation levels, providing a more economical, environmentally friendly, and efficient technological path for the modern metallurgical industry.

First, the rotary furnace offers excellent heat transfer efficiency. Its continuous rotation constantly stirs and mixes the material within, increasing its contact area with the hot flue gases, enhancing heat exchange, improving heat utilization, reducing heat loss, and lowering fuel consumption. Reverberatory furnaces, on the other hand, rely on static heating, resulting in uneven heating of the material and lower thermal efficiency.

Second, the rotary furnace offers high smelting intensity, rapid reaction speed, and high processing capacity. The rotation of the furnace not only promotes heat transfer but also accelerates chemical reactions and physical melting, shortening the smelting cycle and increasing material throughput per unit time. This makes it suitable for large-scale continuous production and improves production efficiency. Furthermore, rotary kilns have a wide range of material adaptability and can effectively process a variety of raw materials, including powders and granules. They are particularly suitable for tin smoke, return materials, and slag with complex compositions, facilitating the optimization of raw material ratios and comprehensive resource utilization. Reverberatory furnaces are prone to problems such as large fly ash losses and incomplete reactions when processing fine-grained materials.

Finally, rotary kilns are easy to automate. Their continuous feeding, rotation, and discharging processes are suitable for integration with modern control systems, enabling precise adjustment of process parameters and automated management of production processes, improving product quality stability and reducing manual operation intensity and errors.

To sum up, the rotary furnace has become an important technical direction to replace the traditional reverberatory furnace in tin concentrate smelting due to its advantages such as efficient heat transfer, strong smelting capacity, wide material adaptability and high degree of automation. It not only improves the smelting efficiency and resource utilization, but also provides equipment support for green and low-carbon smelting.