NEWS&EVENTS

Home > News&Events > Company news > Circulation and filtration system of antimony electrolytic refining equipment

During the electrolytic refining of antimony, the electrolyte is not only a carrier of current but also the medium and core of the entire chemical reaction. The stability of its composition and the uniformity of its physical state directly determine the purity, current efficiency, and energy consumption of the resulting metallic antimony. Therefore, a well-designed and reliable circulation and filtration system, like the "blood circulation system" of the entire refining process, is crucial for ensuring efficient and stable production.

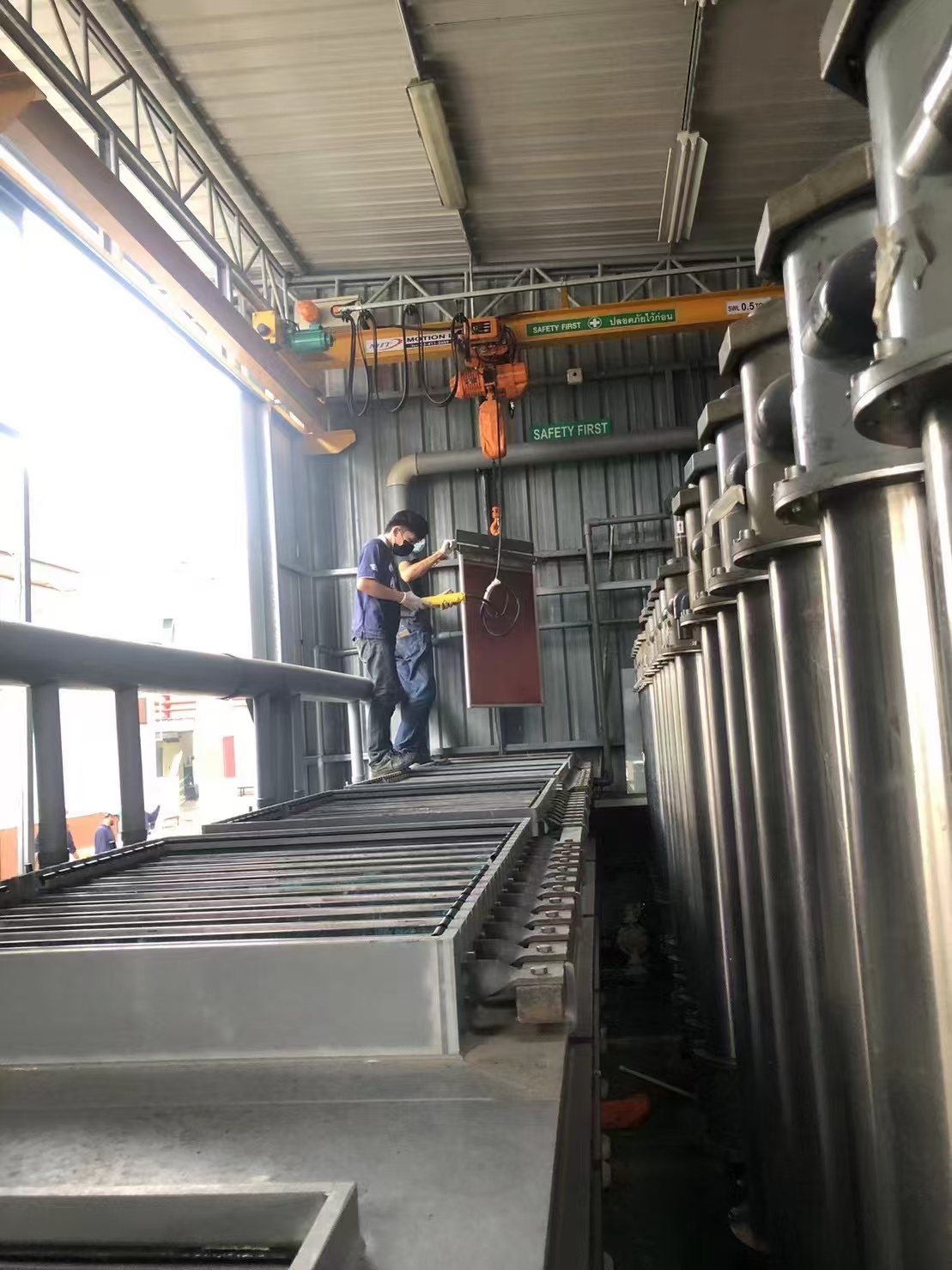

Electrolytic refining uses an electric field to dissolve antimony at the anode and precipitate high-purity antimony at the cathode. However, this process consumes the active ingredients of the electrolyte, generating a high concentration of impurity ions near the anode. This can cause severe concentration polarization when the electrolyte is stationary, affecting the reaction. A circulation system can solve this problem. A corrosion-resistant pump drives the electrolyte circulation, ensuring uniform composition and avoiding local imbalances. It can also control the temperature to ensure the quality of cathode antimony crystals. The circulating electrolyte can carry solid particles, affecting product quality. The filtration system can intercept micron-sized particles to ensure a clean electrolysis environment. In the antimony slurry electrolysis process, the circulating medium is a slurry containing solid antimony ore powder. Flow rate and other factors are the core control factors, requiring powerful stirring and conveying capabilities as well as specialized flow meters and control systems to achieve efficient coordination between leaching and electrolysis.

In summary, the circulation and filtration system in antimony electrolytic refining is not merely ancillary equipment, but rather a core unit that directly determines technical and economic indicators. By maintaining the composition, temperature, and cleanliness of the electrolyte, it provides a solid foundation for efficient, low-energy, and high-quality production.