NEWS&EVENTS

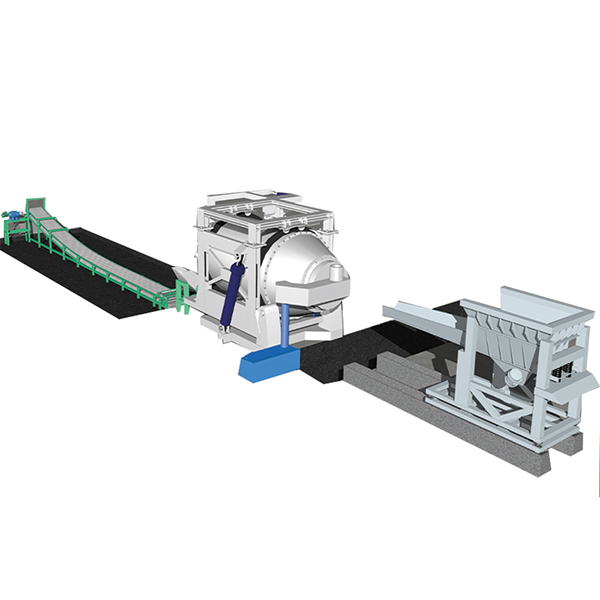

Home > News&Events > Company news > How to prevent and deal with the "ringing" problem in antimony rotary furnace?

During the operation of antimony rotary furnaces, ring formation often occurs. This not only affects production efficiency but can also damage equipment. To effectively prevent and address this problem, the following measures can be taken.

I. Preventive Measures

1. Optimizing Operational Procedures

Stable control of the temperature profile and material residence time is crucial. Precisely adjust the furnace temperature to maintain a suitable range and avoid large temperature fluctuations. Furthermore, appropriately set the material residence time in the furnace to ensure a sufficient and uniform reaction and reduce the risk of ring formation caused by incomplete or overreaction.

2. Strengthening Raw Material Pretreatment

The quality of incoming raw materials directly impacts the operation of the rotary furnace. Strict raw material pretreatment is essential. Screening, washing, and chemical treatment are essential to reduce the content of harmful impurities such as sulfur and arsenic. These impurities react easily with other substances at high temperatures, forming low-melting-point compounds that can cause ring formation.

3. Establishing a Regular Cleaning System

It is crucial to establish a planned system for furnace shutdowns, cleaning, and maintenance. The furnace should be shut down regularly to conduct a comprehensive inspection and cleaning of the furnace, and timely remove any precursors to ringing, such as deposits on the furnace wall. At the same time, the equipment in the furnace should be maintained and serviced to ensure its normal operation.

II. Treatment Measures

When ring formation occurs, the furnace must be shut down immediately for treatment. After the furnace cools, manual cleaning can be performed using tools such as jackhammers and crowbars. In severe cases, manual cleaning may not completely resolve the problem, and relining the refractory may be necessary to ensure the proper operation and service life of the rotary furnace. The above preventive and treatment measures can effectively reduce the frequency of ring formation in antimony rotary furnaces and ensure smooth production.