NEWS&EVENTS

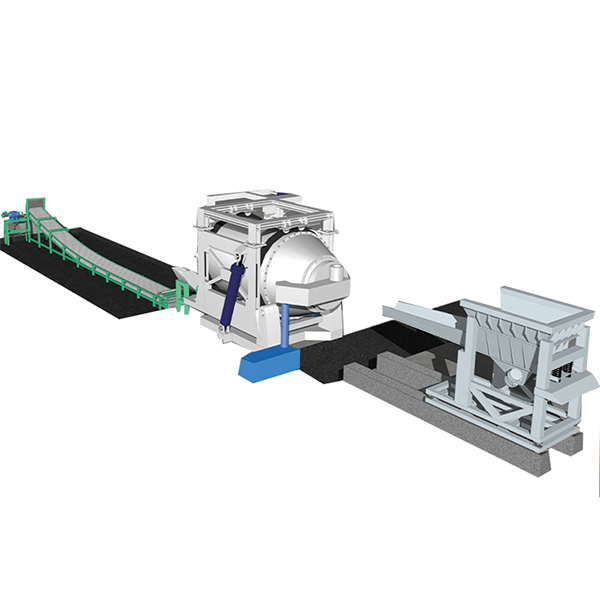

Home > News&Events > Company news > Crude antimony is purified in a rotary refining furnace using a slag-forming method.

Crude antimony produced from rotary kilns typically contains impurities such as iron, copper, arsenic, selenium, and lead. The slag-forming purification method involves adding different refining agents (slag-forming agents) to a refining furnace to chemically react with these impurities, generating low-density, easily separable slag, which is then skimmed off to obtain pure antimony liquid.

一、 Creating "sulfur slag" - removing iron and copper

Iron and copper are the most common metallic impurities in crude antimony. They form hard alloys that affect the brittleness and quality of antimony. Sulfur powder is usually added evenly to the surface of the molten crude antimony and stirred to increase the reaction contact area. The iron sulfide and cuprous sulfide produced by the reaction are insoluble in the antimony liquid and form a layer of dark, loose solid slag floating on the surface, which is called "sulfur slag".

二、Creating "alkali residue" - removing arsenic and selenium

Arsenic and selenium are harmful elements that seriously affect the toxicity and application performance (such as flame retardancy) of antimony products. Typically, soda ash is added, and a small amount of compressed air is blown into the molten pool as an oxidant. The resulting sodium arsenate and sodium selenate form a viscous, glassy liquid scum, known as "alkali slag."

In practice, the order of sulfur-making slag and alkali-making slag is usually fixed. Sulfur is added first to remove iron and copper, followed by alkali to remove arsenic and selenium. This is because adding alkali first may form some intermediate compounds that are difficult to handle.

The slag-forming method is the most crucial and effective chemical purification technique for crude antimony produced in rotary kilns. Utilizing both sulfur slag and alkaline slag, it precisely removes key impurities such as iron, copper, arsenic, and selenium, effectively "washing" the crude antimony into pure refined antimony. This lays a solid foundation for the subsequent production of high-quality antimony ingots or antimony trioxide. This mature, economical, and efficient process is an indispensable refining step in modern antimony smelting.