NEWS&EVENTS

Home > News&Events > Company news > About the manufacturing process of antimony rotary furnace equipment

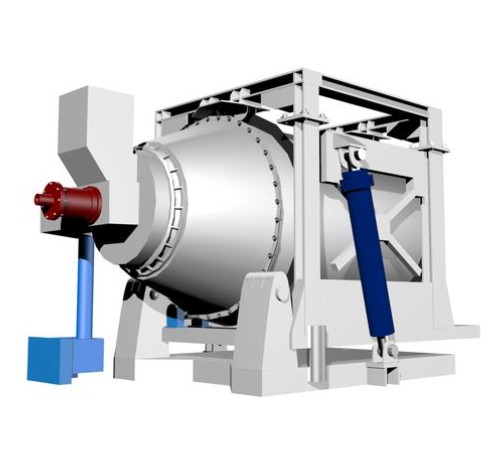

The antimony rotary furnace is the core equipment of the pyrometallurgical antimony smelting process. It is mainly used for volatilization roasting or volatilization smelting of antimony sulfide concentrate, so that antimony can be volatilized in the form of antimony trioxide (Sb2O3) to achieve separation from the gangue. Its key components include furnace body, transmission device, support device, combustion system and flue gas treatment system. The furnace body of the antimony rotary furnace is usually made of high temperature resistant and corrosion resistant 310S stainless steel to adapt to the high temperature redox environment.

1. Manufacturing process

1. Material preparation: According to the use conditions of the equipment, select suitable steel (such as 310S stainless steel) and refractory materials. The furnace body needs to withstand high temperature (900-1200℃) and oxidizing atmosphere, so the material needs to have excellent heat resistance and corrosion resistance.

2. Processing and forming:

Furnace body processing: Use a plate rolling machine to roll the steel plate into a cylindrical shape, and anneal it after welding to eliminate internal stress.

Refractory masonry: Refractory bricks are laid on the inner wall of the furnace or refractory castables are poured to form a protective layer to extend the life of the furnace.

3. Assembly and welding: The furnace body, transmission device, support device and other components are assembled, and automated welding technology is used to ensure sealing and structural strength. Non-destructive testing (such as X-ray flaw detection) is carried out after welding to eliminate defects.

4. Heat treatment: Heat treatment is performed on key components (such as transmission gears) to improve their wear resistance and fatigue strength.

5. Inspection and debugging:

Static inspection: Check the geometric dimensions of the equipment, welding quality and integrity of refractory materials.

Dynamic debugging: Simulate actual working conditions to test the stability of the transmission device, the rotation flexibility of the furnace body and the sealing performance.

2. Key technologies

1. Refractory material selection and masonry: Refractory materials with good thermal shock resistance and corrosion resistance should be selected, and the masonry process should be optimized to ensure stable operation of the furnace body at high temperatures.

2. Furnace body sealing technology: Labyrinth seals or graphite sealing rings are used to prevent flue gas leakage and improve energy utilization.

3. Design of transmission and support device: Optimize the furnace support structure through finite element analysis to ensure that the deformation is controllable at high temperature; the transmission device adopts variable frequency speed regulation to adapt to different working conditions.

4. Combustion system optimization: Design oxygen-enriched combustion technology to improve combustion efficiency, reduce energy consumption, and reduce pollutant emissions.

III. Quality control

1. Raw material inspection: Chemical composition analysis and physical property testing of raw materials such as steel and refractory materials to ensure compliance with standards.

2. Process monitoring: Use CNC machine tools to process key components to ensure dimensional accuracy; implement full quality monitoring during the welding process, and record welding parameters and test results.

3. Finished product inspection: Conduct water pressure test, air tightness test and load test to verify equipment performance.

The manufacturing process of antimony rotary furnace is developing in the direction of high efficiency, energy saving and environmental protection. Combined with new materials and intelligent control technology, it will further improve the resource utilization rate and economic benefits of the antimony smelting industry in the future.