NEWS&EVENTS

Home > News&Events > Company news > Purity and guarantee technology of antimony produced by electrolytic antimony equipment

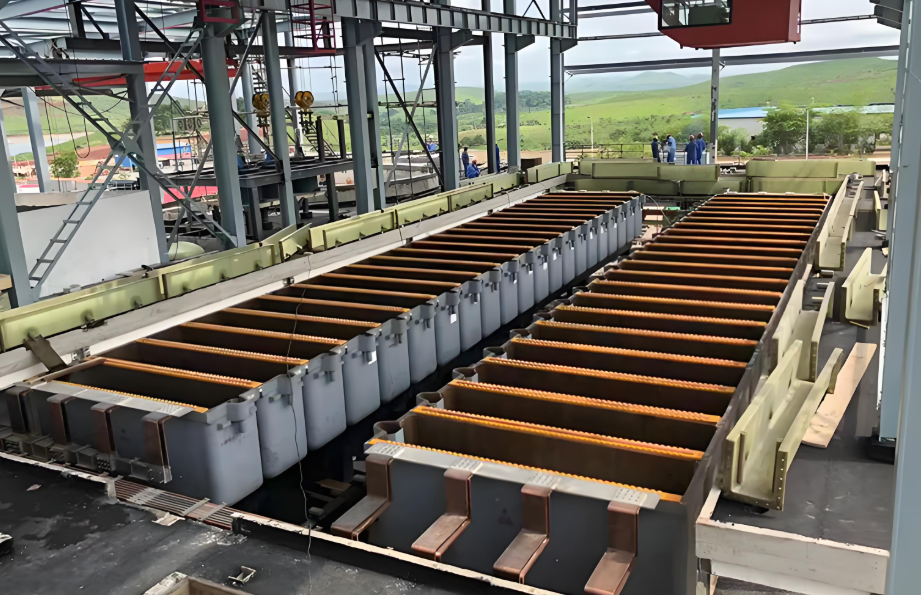

As a professional electrolytic antimony equipment manufacturer, we are well aware of the requirements for equipment performance in the production of high-purity antimony metal. The electrolytic equipment we produce has significant advantages in helping antimony metal produce high-purity products, generally reaching more than 99.9%, and the purity of some high-end products can even reach 99.99%.

Our electrolytic antimony equipment shows unique advantages in the raw material processing link. The equipment is equipped with an advanced raw material screening system, which can strictly control the raw materials entering the electrolysis process and accurately control the impurity content in the raw materials, laying the foundation for high-purity production from the source, and effectively reducing the potential impact of impurities on product quality.

In terms of electrolyte treatment, our equipment performs even better. The built-in efficient purification system can use a series of advanced technologies such as chemical precipitation, ion exchange, and membrane separation to deeply remove impurity ions such as copper, iron, and lead in the electrolyte, ensuring that the electrolyte always maintains high purity and providing a high-quality environment for the electrolysis process.

During the electrolysis process, the equipment has the ability to accurately control parameters. By precisely controlling important parameters such as current density, electrolysis temperature, and electrolyte circulation speed, the electrolysis conditions are continuously optimized to effectively reduce the co-deposition of impurities at the cathode. At the same time, the equipment uses a special electrode structure and high-quality materials to prevent impurities in the electrode material from dissolving and mixing into the electrolyte, further improving product quality.

Our electrolytic antimony equipment can also play a key role in the post-processing stage of the product. With advanced process flow, the metal antimony obtained by electrolysis is further refined and purified, and vacuum distillation and other processes are used to remove the trace impurities remaining in it. After this series of rigorous and meticulous process flows, high-purity metal antimony products are finally produced to meet the market demand for high-quality metal antimony and demonstrate the excellent performance of our electrolytic equipment.