NEWS&EVENTS

Home > News&Events > Company news > Advantages and disadvantages of rotary furnace pyrometallurgy to produce high purity antimony

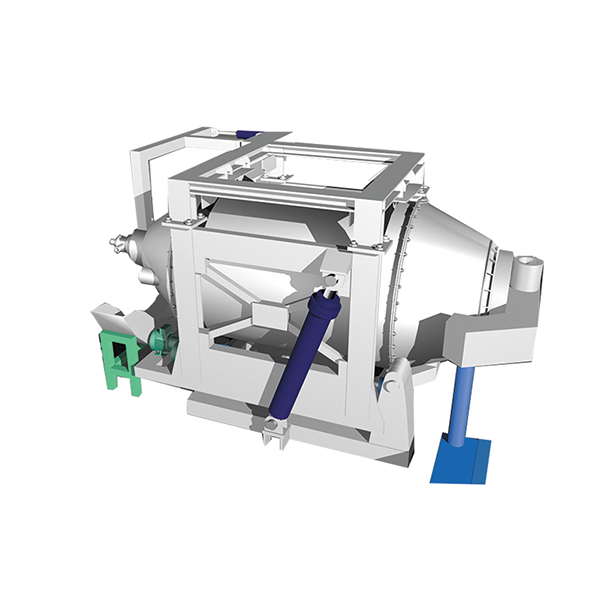

In the smelting process of antimony, rotary furnace pyrometallurgy is an important method for producing high-purity antimony. It has many advantages, but also some disadvantages that cannot be ignored.

The advantages of rotary furnace pyrometallurgy are significant. First, it can achieve continuous production. During the production process, the materials can continuously enter the rotary furnace for reaction, and the products after the reaction can be discharged in time. This continuous production mode greatly improves production efficiency, reduces the time waste and equipment start-up and shutdown losses caused by intermittent production, and brings higher economic benefits to the enterprise. Secondly, impurities are separated thoroughly. Through the two key steps of oxidation volatilization and vacuum distillation, the rotary furnace can effectively remove various impurities in the raw materials, and finally produce high-purity antimony with a purity of 99.99% or more, which meets the strict requirements of antimony purity in the high-end field. Furthermore, it has strong adaptability. Whether it is low-grade antimony raw materials or complex antimony-containing materials, such as antimony-lead alloys, antimony-gold mines, etc., the rotary furnace can effectively process them, broaden the source range of raw materials, and reduce production costs.

However, rotary furnace pyrometallurgy also has some disadvantages. On the one hand, the energy consumption is high. The process needs to be heated in a high temperature environment and needs to maintain a vacuum state, which undoubtedly increases energy consumption and increases production costs. On the other hand, the equipment is complex. The rotary furnace needs to accurately control multiple parameters such as temperature, atmosphere and rotation speed during operation, which has extremely high technical requirements. Once a certain link deviates, it may affect product quality and production safety. In addition, harmful gases such as SO₂ will be produced in the oxidation stage, which requires the construction of a special desulfurization device, increasing the company's environmental protection investment and operating costs.

In summary, although the rotary furnace smelting method for producing high-purity antimony has advantages, it also faces some challenges and needs to be continuously optimized and improved in production practice.