NEWS&EVENTS

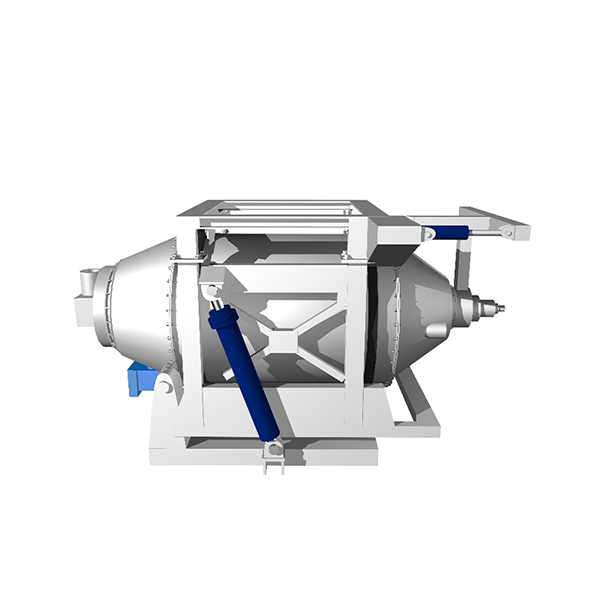

In the field of antimony ore smelting, the rotary furnace, as an important smelting equipment, stands out among many smelting furnace types with its unique design and excellent performance. It provides a reliable guarantee for the efficient smelting of antimony ore. Let us take a deeper look at the key advantages of the rotary furnace for antimony ore smelting.

1. Efficient heat transfer and uniform heating

The dynamic rotation characteristics of the rotary furnace enable the antimony ore particles to continuously renew their surface in the furnace and fully contact the heat source, greatly improving the heat transfer efficiency. Compared with traditional static furnace types, the rotary furnace can achieve more uniform heating and avoid the occurrence of local overheating or underheating. This not only shortens the smelting time and improves production efficiency, but also effectively reduces energy consumption and reduces production costs.

2. Flexible process adaptability

The rotary furnace can flexibly adjust the process parameters according to different antimony ore grades, compositions and smelting requirements. For example, for high-grade antimony ore, a higher temperature and a shorter residence time can be used to quickly volatilize antimony; for low-grade antimony ore, the temperature can be appropriately lowered, the residence time can be extended, and an appropriate amount of flux can be added to improve the recovery rate of antimony. In addition, the rotary furnace can easily switch between different fuel types to adapt to different energy supply conditions.

3. Good material mixing and reaction conditions

During the rotation of the rotary furnace, antimony ore is fully mixed with materials such as reducing agents and fluxes, providing good conditions for chemical reactions. Uniform material distribution helps to increase the reaction rate and degree and reduce the occurrence of side reactions. At the same time, the dynamic environment in the furnace can also promote gas diffusion and mass transfer, making the reaction more thorough.

In summary, the antimony ore smelting rotary furnace plays an important role in the antimony ore smelting industry with its key advantages such as efficient heat transfer and uniform heating, flexible process adaptability, and good material mixing and reaction conditions. With the continuous advancement of technology, it is believed that the antimony rotary furnace will continue to be optimized and upgraded, bringing more benefits and development opportunities to the antimony ore smelting industry.