NEWS&EVENTS

As an important strategic metal, antimony is widely used in many fields. The preparation of antimony ore to antimony trioxide powder requires many complex and professional processes.

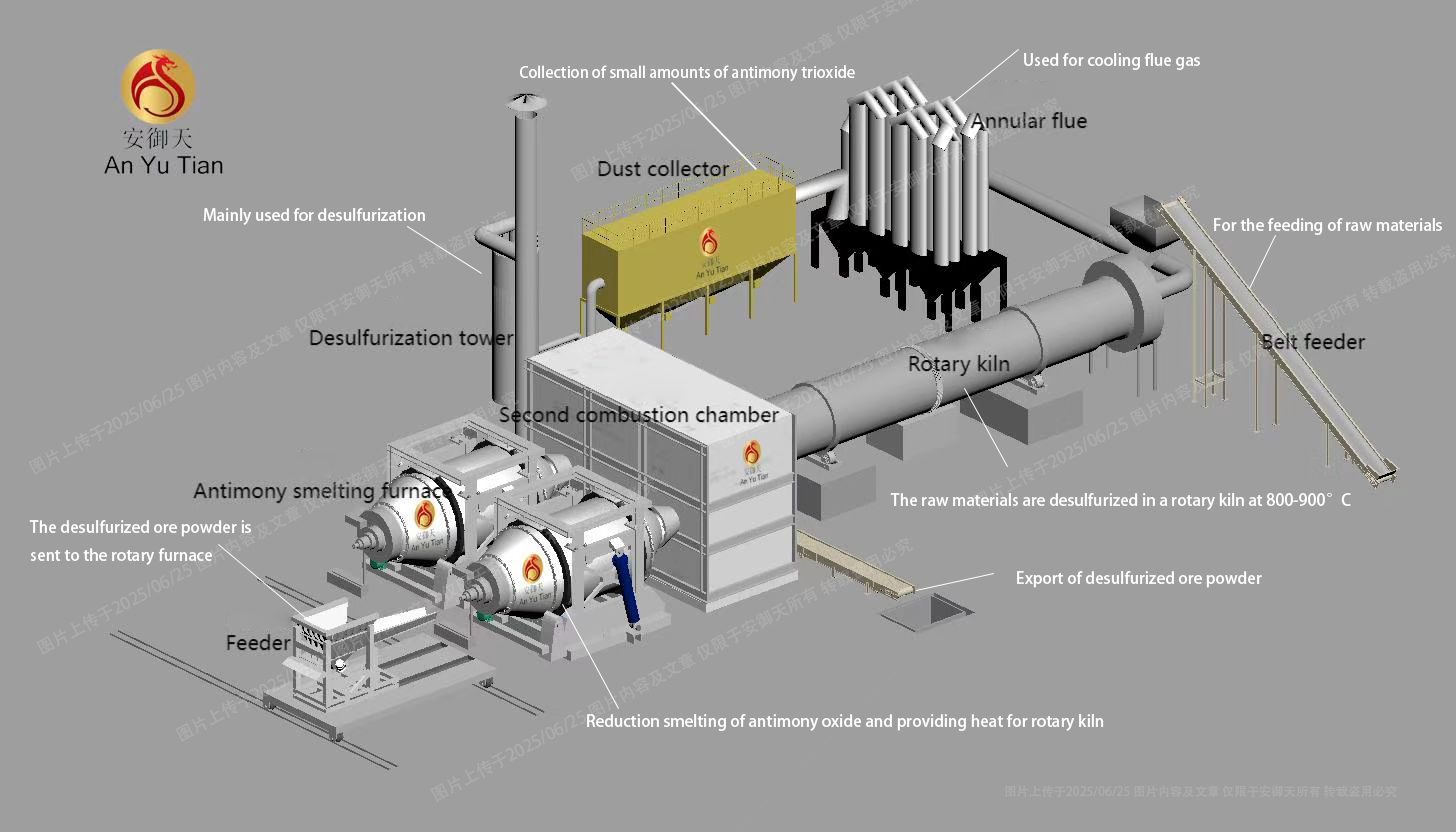

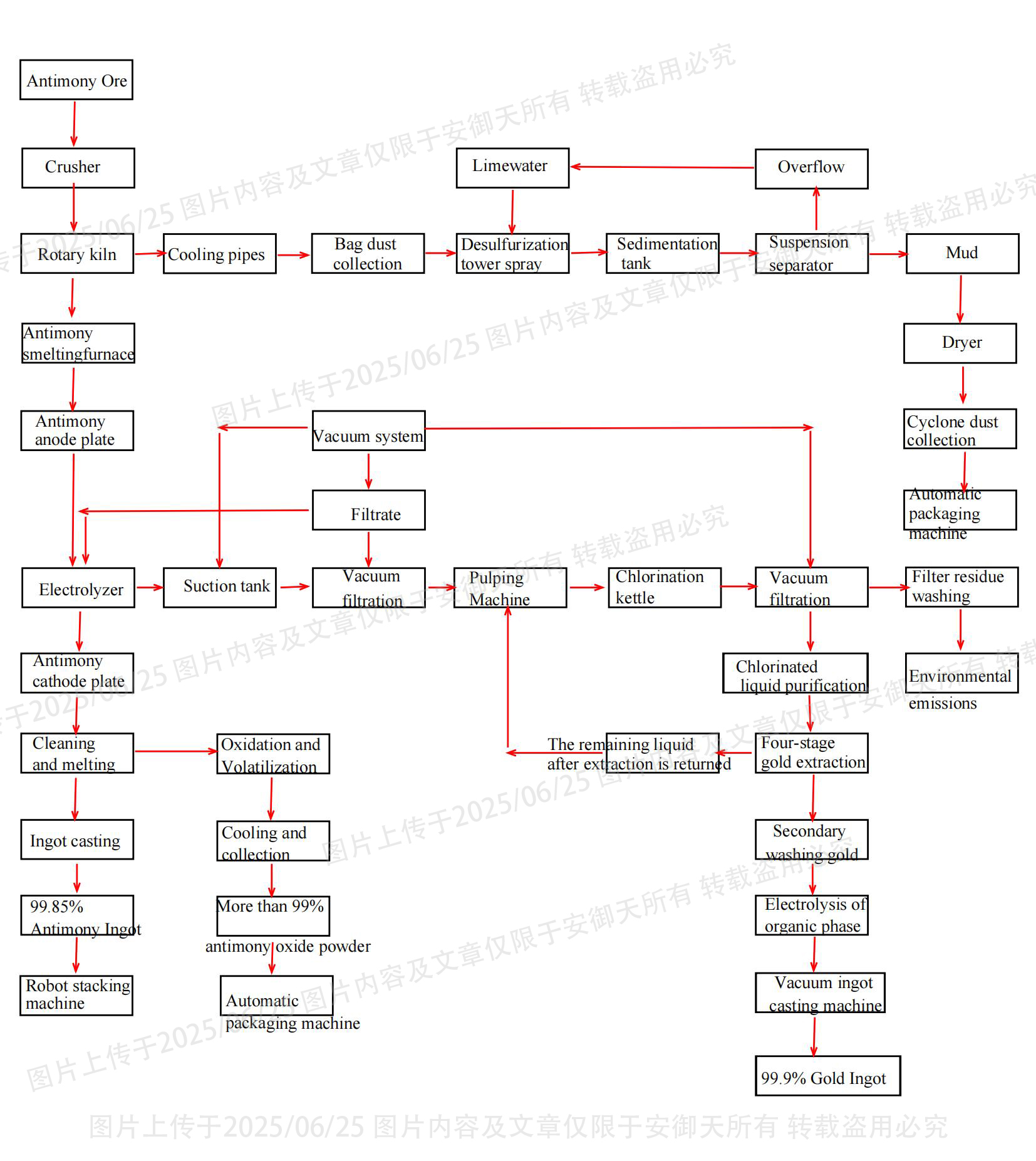

The main component of antimony ore is stibnite (Sb₂S₃), which requires high-temperature desulfurization in a rotary furnace. The ore is roasted at 800-1000℃ and limited air is introduced. Sulfur is oxidized to SO₂ gas and escapes, resulting in antimony oxide powder rich in antimony oxide. This step achieves antimony-sulfur separation and lays the foundation for subsequent metal reduction.

The antimony ore powder after desulfurization treatment is then sent to the high-temperature reduction smelting stage. A reducing agent is added to the rotary furnace, and under high temperature conditions of about 1200°C, antimony oxide is reduced to finally produce crude antimony. Since crude antimony contains impurities, it needs to be melted and cast into antimony anode plates in order to enter the electrolytic refining stage. In the electrolytic cell, the antimony anode plate is used as the anode, and electricity is turned on for electrolysis under a specific electrolyte system. In this process, the antimony at the anode dissolves into the electrolyte, while elements such as silver and gold remain in the anode mud. It is worth mentioning that the anode mud can further recover valuable elements such as silver and gold. At the same time, high-purity antimony is precipitated at the cathode to form cathode antimony, which is then smelted and cast again to finally be made into high-purity antimony ingots.

To produce the key product Sb2O3 powder, high-purity antimony ingots need to undergo remelting and high-temperature evaporation oxidation. Antimony ingots are melted in a special oxidation furnace (~1000°C), and the molten antimony is violently volatilized and oxidized in a high-temperature, strong oxidizing atmosphere (air or oxygen-rich air). The generated gaseous Sb2O3 is rapidly condensed into fine cubic Sb2O3 powder in the quenching zone (such as bag dust collection). This process requires precise control of temperature, atmosphere and condensation rate to obtain flame-retardant products with uniform particle size, high whiteness and excellent reactivity.

The entire preparation process has extremely strict requirements on process parameters, from temperature control of pyrometallurgy to current and voltage regulation of electrolytic refining, to optimization of reaction conditions of high-temperature evaporation oxidation, each link affects the quality and purity of the final product. Only by precisely controlling each link can we prepare antimony trioxide powder that meets high standards and meets the needs of industries such as electronics, chemicals, and flame retardant materials.