NEWS&EVENTS

Home > News&Events > Company news > Advantages of pyrometallurgy (rotary furnace) to produce antimony trioxide by treating antimony ore

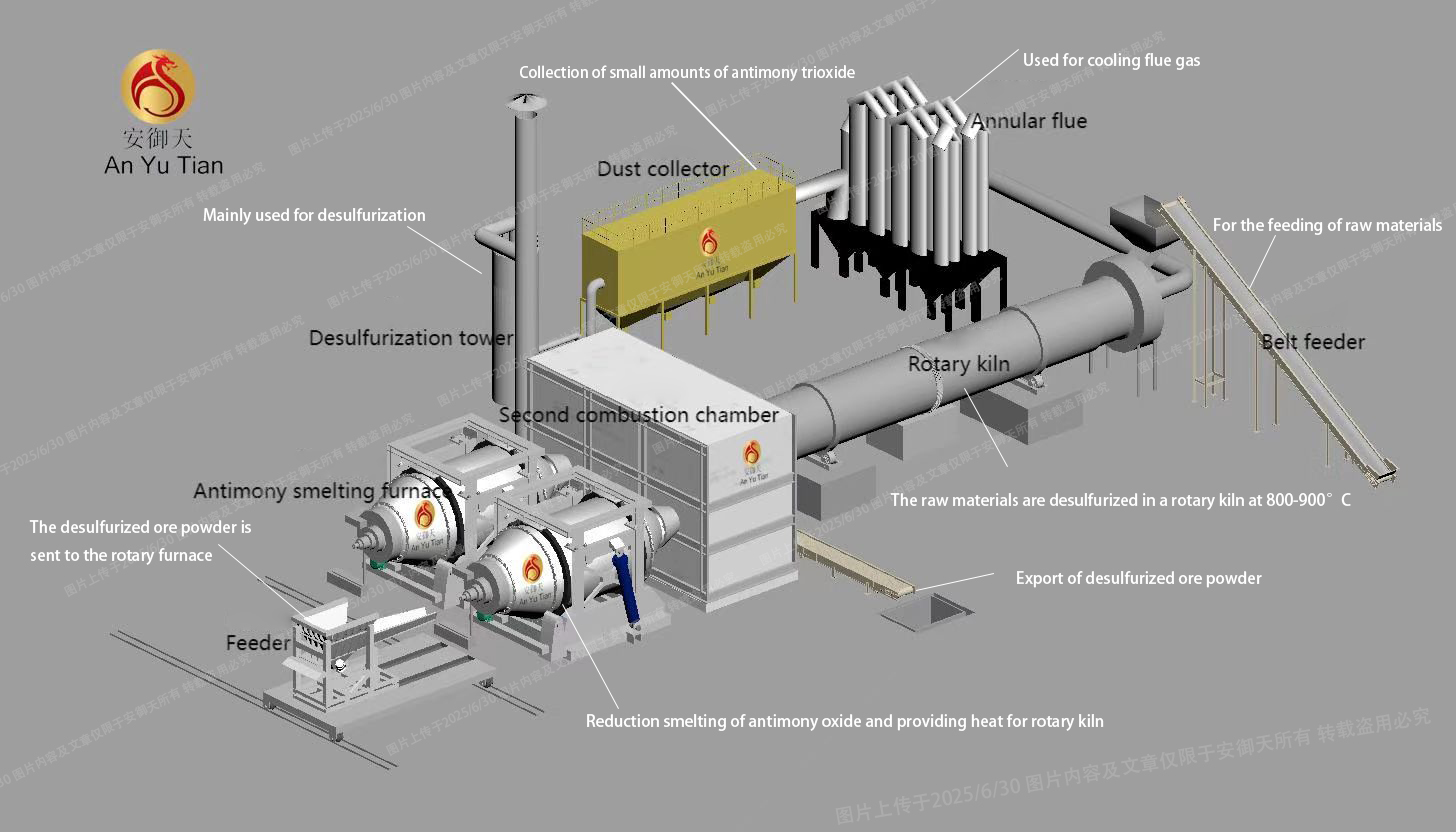

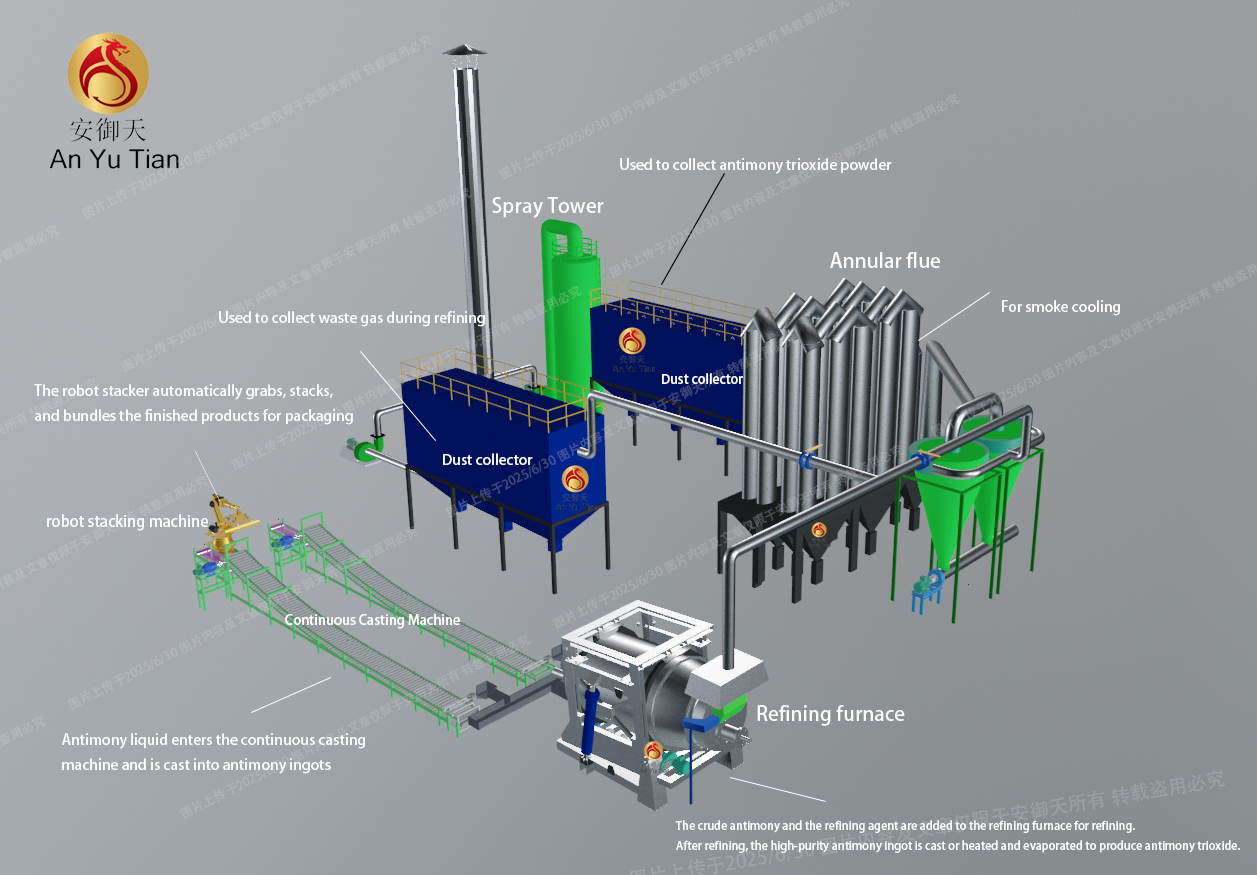

Pyrometallurgy (especially using rotary furnace) to treat antimony ore to produce antimony trioxide (Sb2O3) is a mature and widely used process. Compared with other methods (such as hydrometallurgy, etc.), it has the following significant process advantages:

1. Strong adaptability to raw materials: It can process medium and low-grade antimony ores and complex antimony ores containing impurities.

2. Operation continuity and automation: It can realize continuous operation of feeding and discharging, with high production efficiency and equipped with advanced automated production systems, which reduces labor intensity.

3. High metal recovery rate: Thanks to efficient volatilization and advanced dust collection technology (such as high-efficiency bag dust collectors), the total recovery rate of antimony can usually be stabilized at more than 95%, even reaching 97%-98%, which is one of the processes with higher recovery rates in pyrometallurgy.

4. Stable product quality: By controlling the roasting temperature, atmosphere (oxidizing property) and dust collection conditions, crude antimony with high purity can be produced, providing a good raw material basis for subsequent refining. The antimony oxide powder obtained by bag dust collection has fine particle size and good activity.

5. Relatively low energy consumption: Compared with other processes, the temperature of rotary furnace volatilization roasting is relatively low. When processing the same grade of antimony ore, the fuel consumption is usually lower than other processes.

6. Mature and reliable equipment: Rotary furnace is a mature equipment widely used in metallurgy, chemical industry, building materials and other industries, with rich experience in design, manufacturing, installation and maintenance, and high operational reliability.

7. Significant equipment cost advantage: Compared with electrolytic slurry electrolysis equipment, its price is lower.

The core advantages of rotary furnace pyrometallurgy to produce Sb2O3 from antimony ore are high recovery rate, continuous operation, relatively easy control, and relatively reasonable energy consumption. Its technical maturity and comprehensive benefits make it still occupy a dominant position in the global antimony smelting field, especially in the treatment of mainstream medium and low-grade antimony ores. The core competitiveness of modern rotary furnace technology lies in its volatilization efficiency and supporting high-efficiency environmental protection facilities.