NEWS&EVENTS

Home > News&Events > Company news > Precise monitoring and stable control of antimony trioxide production process

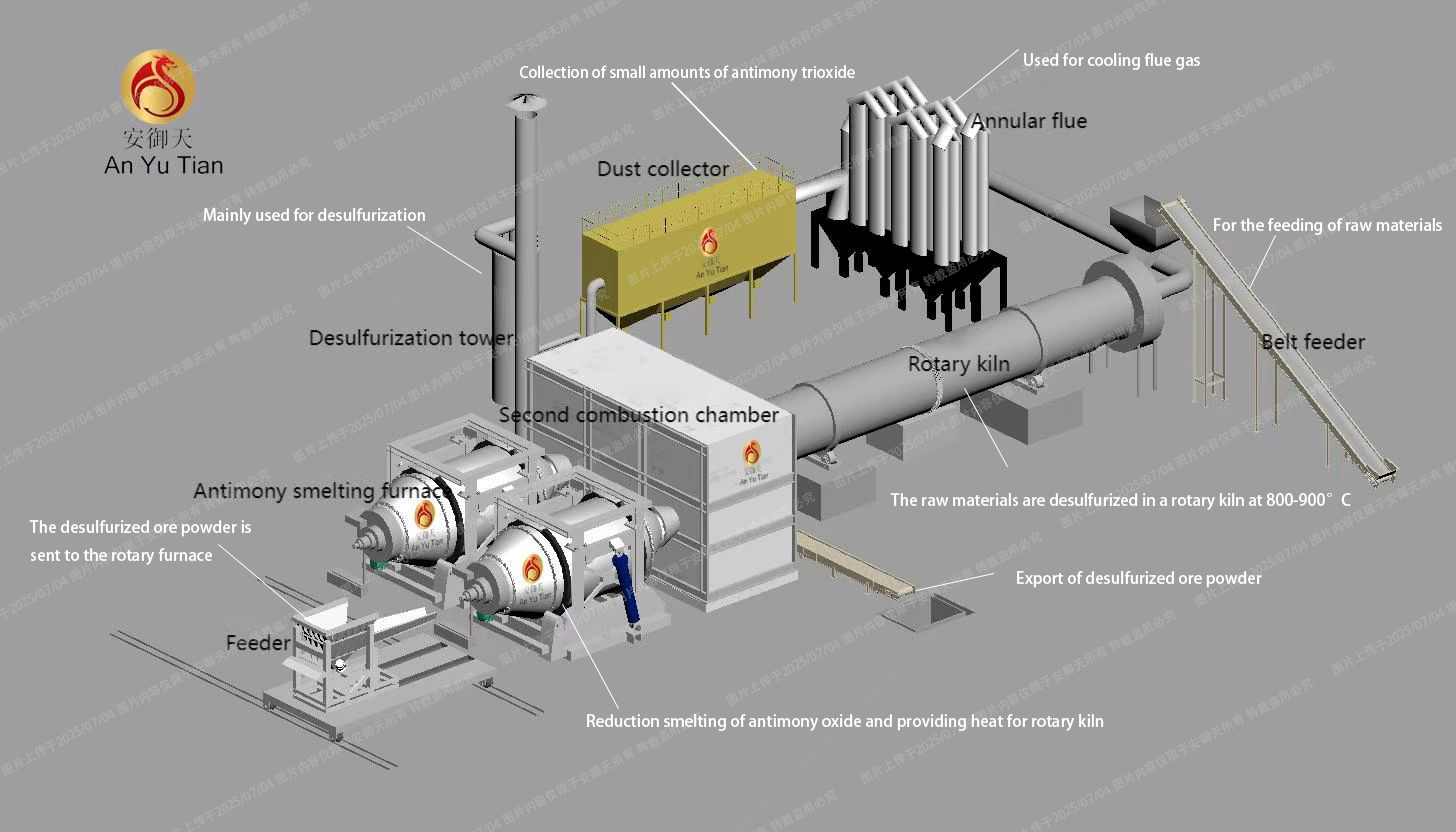

In actual production, in order to ensure the stable operation of the preparation process of antimony trioxide powder and the continuous improvement of product quality, a complete monitoring and control system needs to be established. In the pyrometallurgical smelting stage, high-precision temperature sensors are installed at key parts of the rotary furnace to monitor the temperature changes in the furnace in real time and transmit the data to the central control system. Once the temperature deviates from the set range, the system automatically adjusts the fuel supply or ventilation volume to ensure that the roasting and reduction smelting processes are carried out under the optimal temperature conditions to avoid problems such as insufficient reduction of antimony oxide or excessive impurity generation due to temperature fluctuations.

In the electrolytic refining stage, in addition to accurately controlling the current and voltage, the composition and concentration of the electrolyte must be regularly tested and analyzed. Advanced online analytical instruments are used to grasp the changes in parameters such as antimony ions, impurity ions, and pH in the electrolyte in real time. According to the test results, the electrolyte replenishment and circulation speed are adjusted in time to ensure that the electrolysis process is always in a stable chemical equilibrium state, thereby improving the purity and current efficiency of the cathode antimony. At the same time, the treatment of anode mud also needs to be strictly controlled. Advanced hydrometallurgical technology is used to recover valuable elements such as silver and gold through multi-stage leaching, extraction and purification, so as to achieve comprehensive utilization of resources and maximize economic benefits.

During the high-temperature evaporation oxidation process, the control of the atmosphere in the oxidation furnace is crucial. By precisely adjusting the flow and pressure of air or oxygen-enriched air, it is ensured that the furnace always maintains a high-temperature and strong oxidizing atmosphere, so that the molten antimony can fully volatilize and be oxidized to generate gaseous Sb2O3. In the quenching zone, advanced condensation technology and equipment are used, such as high-efficiency bag dust collectors with optimized airflow distribution design, so that gaseous Sb2O3 can be quickly and evenly condensed into fine cubic crystal powder.