NEWS&EVENTS

Home > News&Events > Company news > Principle of the rotary furnace desulfurization process for producing Sb2O3 powder

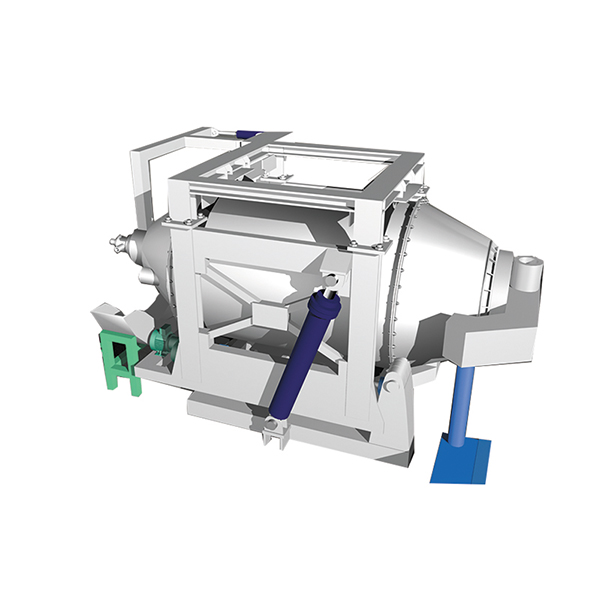

In the industrial preparation process of antimony trioxide (Sb2O3), the rotary kiln desulfurization process is a key link that determines product quality and environmental benefits. When antimony ore (Sb2O3) is used as the main raw material, the removal and conversion of sulfur is directly related to the purity of the final product and the environmental performance of the production process.

The pyrometallurgical process achieves antimony and sulfur separation through high-temperature oxidation. In a rotary furnace, stibnite is roasted at 800-1000℃, and limited air is introduced to control the oxidation reaction process. This temperature range is precisely designed: below 600℃, antimony sulfide is not completely oxidized, and residual sulfur will reduce the purity of the product; exceeding 800℃ may cause Sb2O3 to volatilize, resulting in raw material loss. Under high temperature, the sulfur in Sb2S3 is selectively oxidized to sulfur dioxide (SO2) gas, while the antimony element is converted into solid antimony oxide to form antimony oxide powder rich in Sb2O3. This process not only achieves efficient separation of antimony and sulfur, but also lays a material foundation for the subsequent reduction and extraction of metallic antimony.

For the SO2-containing flue gas produced by roasting, the modern process adopts a multi-stage treatment system: first, the particulate matter is captured by an electrostatic precipitator, and then the desulfurization tower is used for wet or dry desulfurization. This closed-loop treatment mode not only avoids the pollution of the atmosphere by direct SO2 emissions, but also realizes the recycling of sulfur resources.

The dual value of the rotary furnace desulfurization process is significant: in terms of the environment, acid gas emissions are greatly reduced through gaseous sulfur conversion and flue gas purification; in terms of quality, deep desulfurization increases the purity of Sb2O3 to more than 99.5%, meeting the stringent requirements for raw materials in high-end fields such as flame retardants and catalysts. With the upgrading of environmental protection standards, the technical optimization of this process is continuously evolving towards waste heat recovery and high-value utilization of by-products, promoting the transformation of the antimony smelting industry to green manufacturing.