NEWS&EVENTS

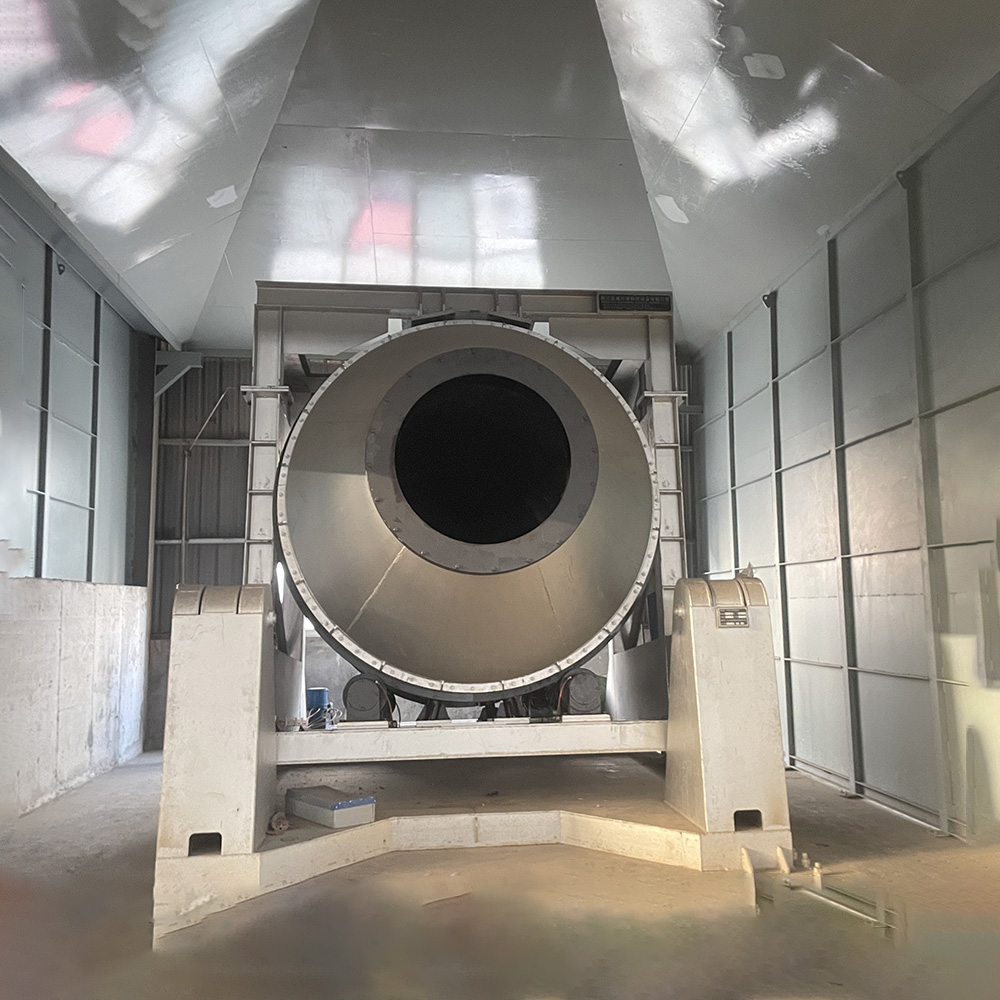

Home > News&Events > Company news > Antimony rotary furnace high temperature reduction smelting stage

During the high-temperature reduction smelting stage of the rotary furnace, many factors affect the reduction effect of antimony oxide and the quality of crude antimony, mainly involving the addition of reducing agents, temperature and atmosphere control, and equipment operation and maintenance.

1. Accurate control of reducing agent addition

It is crucial to accurately control the amount and time of reducing agent addition. If the amount added is insufficient, antimony oxide cannot be fully reduced, resulting in a decrease in the output of crude antimony, and unreduced oxides may remain in it, affecting the purity; excessive addition not only causes waste, but also causes the excess reducing agent to react with other substances in the furnace at high temperature to generate impurities mixed into the crude antimony, reducing its quality. In order to ensure that the reducing agent is evenly dispersed, the rotary furnace is often equipped with a special distribution device. Through reasonable structural design, the reducing agent can be evenly distributed in the furnace when added. At the same time, the rotation of the rotary furnace can further promote its full contact with antimony oxide and improve the rate and degree of the reduction reaction.

2. Fine control of temperature and atmosphere

The rotary furnace adopts an advanced temperature control system, which monitors the temperature in real time through thermocouples and other temperature measuring elements, and feeds back to the control system to automatically adjust the heating power to achieve precise temperature control. If the temperature is too high, the reduction reaction will be too intense, resulting in the loss of some antimony by volatilization, and may also cause side reactions, affecting the composition of crude antimony; if the temperature is too low, the reduction reaction rate will slow down or even fail to proceed, reducing production efficiency. In terms of creating a reducing atmosphere, the gas flow and composition are precisely controlled, and the pressure in the furnace is adjusted to ensure the smooth progress of the reduction reaction. A suitable reducing atmosphere can promote the reduction of antimony oxides, and at the same time, it is conducive to the volatilization and removal of impurities, thereby improving the quality of crude antimony.

3. Guarantee of equipment operation and maintenance

Under long-term high-temperature operation, the rotary furnace is prone to problems such as lining wear and refractory material shedding. Daily maintenance requires regular inspection of the furnace body and timely repair or replacement of damaged parts. In a high-temperature environment, the transmission system should use high-temperature resistant and wear-resistant materials, and strengthen lubrication and cooling to ensure its reliability and stability. Failure of the transmission system will cause the rotary furnace to stop, causing material accumulation and uneven heating, which will seriously affect the reduction smelting process and product quality.