NEWS&EVENTS

The process principle of the antimony rotary furnace is a combination of high-temperature reduction reaction and heat energy recycling. In the rotary furnace, the ore powder that has been initially roasted and desulfurized in the rotary kiln undergoes complex physical and chemical reactions with the reducing agent (such as coke and coal powder) at high temperature. This temperature allows antimony oxide (such as antimony trioxide) to fully contact with the reducing agent, reducing antimony from the compound to the metal state. The reaction formula is Sb₂O₃ + 3C → 2Sb + 3CO↑. The rotary furnace rotates slowly to mix the ore powder and the reducing agent evenly, ensuring sufficient reaction. It can also extend the residence time of the material in the high temperature zone and improve the reaction conversion rate.

In terms of heat energy recycling, the rotary furnace and the rotary kiln form an efficient heat energy transfer system. The high-temperature flue gas generated by the rotary furnace smelting is guided to the rotary kiln through pipes and heat exchange devices to provide heat for ore roasting. This method reduces additional energy input, and the energy utilization rate is 30%-40% higher than the traditional independent heating method, reducing production costs.

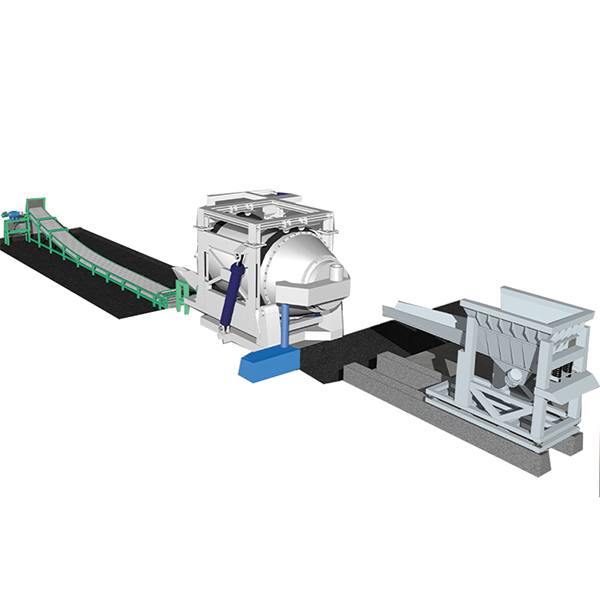

The advantages of antimony rotary furnace are obvious. In terms of product quality, precise temperature control and uniform material mixing make the smelted crude antimony metal high in purity and low in impurities, providing good raw materials for subsequent refining. In terms of production efficiency, it has strong continuous operation capacity, can continuously feed, smelt and discharge materials, shorten the production cycle, and increase the output per unit time. It has good environmental performance, and the reasonable flue gas treatment system cools, removes dust, desulfurizes and purifies high-temperature flue gas, reduces the emission of harmful substances, and the recycling of heat energy also reduces waste gas emissions. In addition, its equipment has a simple structure, consisting of a furnace body, a transmission device, etc., with reasonable connections and coordination, and easy operation and maintenance. Operators can master skills after training, deal with small problems in a timely manner, and ensure the stable operation of the equipment and the smooth processing of antimony ore.