NEWS&EVENTS

Home > News&Events > Company news > How to efficiently recover antimony-containing dust generated during antimony volatilization

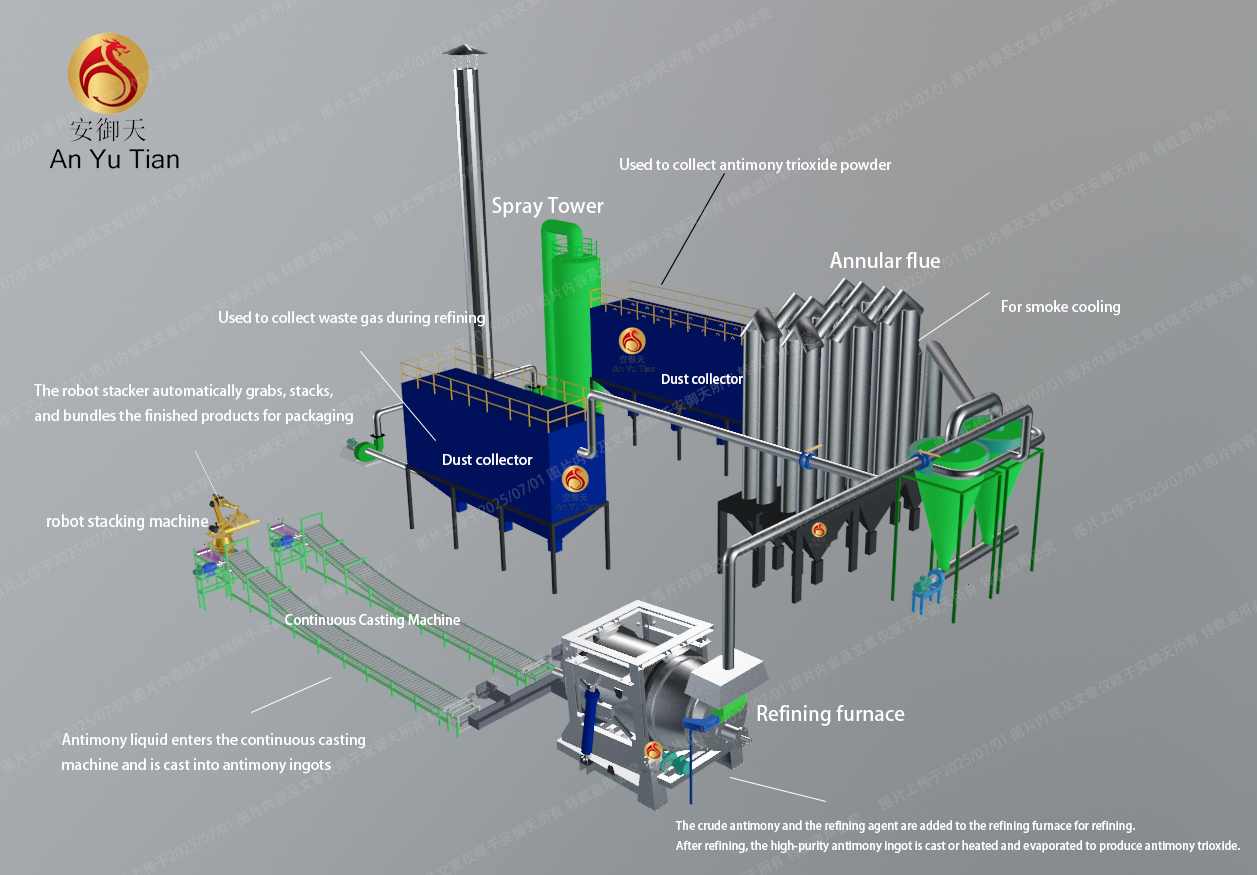

When antimony is volatilized to produce antimony oxide powder, antimony-containing dust will escape with the volatile gas. If it cannot be recovered efficiently, it will not only waste antimony resources but also pollute the environment. Bag dust collectors bear the heavy responsibility of efficiently recovering antimony-containing dust in this link.

Antimony trioxide gas volatilized at high temperature carries antimony-containing dust into the bag dust collector, which has many filter bags made of special fiber materials inside, which have good air permeability and filtration performance. The dust-containing gas flows evenly to the filter bag through the air inlet under the action of the guide device. Large dust particles are attached to the surface of the filter bag due to inertia impact; smaller particles shuttle between the filter bag fibers with the air flow, and are captured and deposited on the surface of the filter bag under Brownian motion and fiber interception.

As the filtration proceeds, the dust layer on the surface of the filter bag thickens, improving the filtration efficiency. When the dust layer reaches a certain thickness, the dust collector automatically starts the cleaning system. The cleaning methods include pulse blowing, mechanical vibration, etc. Taking pulse blowing as an example, compressed air is sprayed into the filter bag at high speed in a very short time, causing the filter bag to expand and vibrate, and shake off the dust. The dust falls into the ash hopper and is discharged regularly through the ash discharge device for centralized collection and treatment.

The efficient recovery of bag dust collectors is due to precise design and reasonable operating parameters. The filter bag material should be selected according to the characteristics of antimony-containing dust, and materials with high temperature resistance, corrosion resistance and high filtration accuracy should be selected. At the same time, the wind speed, filtration area and other parameters of the dust collector are carefully calculated and optimized to ensure the processing air volume and achieve efficient recovery.

The bag dust collector efficiently recovers antimony-containing dust, improves the utilization rate of antimony resources, reduces production costs, reduces dust emissions, and protects the environment. In the entire antimony ore processing process, it works closely with rotary kilns, refining furnaces and other equipment to build an efficient and environmentally friendly production system, providing a strong guarantee for the sustainable development of the antimony industry.