NEWS&EVENTS

Home > News&Events > Company news > Advantages of the combined process of pyrometallurgy and electrolysis of antimony ore

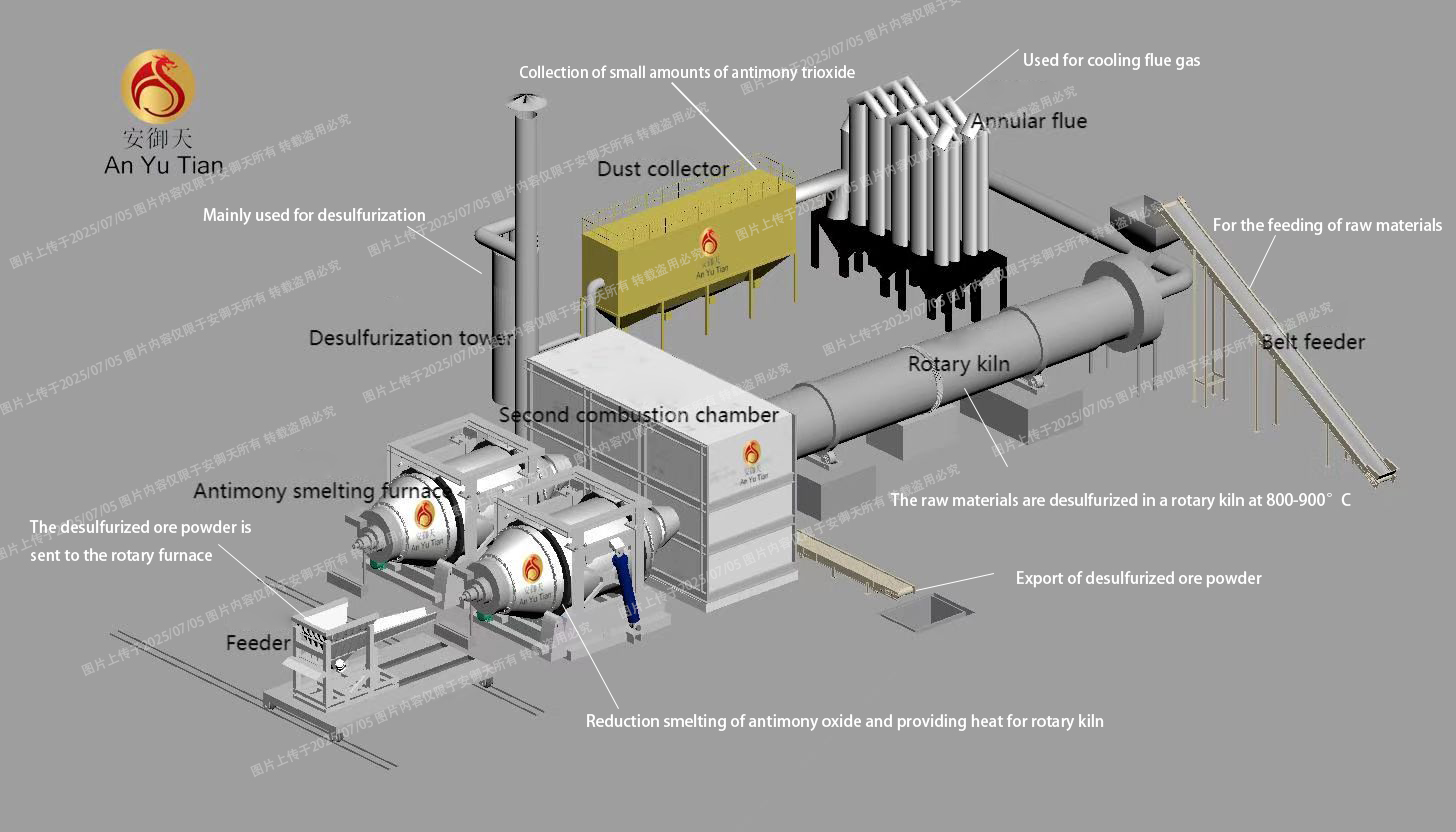

In the antimony ore preparation process, the advantages of the pyrometallurgical process involving the rotary furnace and the electrolytic combined process dominated by electrolytic equipment are significant, which runs through the entire antimony production process and is of great significance to improving quality, reducing costs, and comprehensively utilizing resources.

From the perspective of production efficiency, the pyrometallurgical smelting in the rotary furnace can quickly separate antimony and sulfur through high-temperature roasting and reduction smelting, produce crude antimony, achieve initial enrichment of antimony elements, and provide pure raw materials for electrolytic refining. Electrolytic refining uses electrochemical principles to precipitate antimony at the cathode and leave impurities in the anode mud. The combination of the two avoids the efficiency bottleneck of a single process, shortens the production cycle, and improves overall efficiency.

In terms of product quality improvement, this process has outstanding advantages. Although the rotary furnace pyrometallurgical smelting can remove most impurities such as sulfur, crude antimony still remains. Electrolytic refining can separate and remove these impurities with precise electrochemical control, such as leaving precious metals such as silver and gold in the anode mud to achieve efficient separation from antimony. After double purification, the quality of high-purity antimony ingots is stable, meeting the needs of many industries for high-quality antimony products.

In terms of comprehensive resource utilization and environmental protection, the rotary furnace pyrometallurgy reasonably controls the roasting conditions, so that sulfur escapes as sulfur dioxide gas and is collected to make sulfuric acid, reducing pollutant emissions. The anode mud produced by electrolytic refining is rich in precious metals, and recycling can improve the comprehensive utilization rate of resources. The combined process optimizes parameters, reduces energy consumption and waste emissions, and conforms to the concept of green development.

In terms of cost control, the rotary furnace pyrometallurgy equipment is simple and the operating cost is low, which can achieve the initial treatment and enrichment of antimony ore at low cost. Although the cost of electrolytic refining is high, the production of high-purity products increases added value, and the comprehensive recovery of sulfur resources and precious metals further reduces costs and improves the economic benefits of enterprises.

In short, the combined process has obvious advantages in many aspects. It is a key technology for the efficient, green and sustainable development of the antimony industry, and also provides a reference for the development and utilization of other metal mineral resources.