NEWS&EVENTS

Home > News&Events > Company news > From antimony ore to antimony trioxide powder, which link consumes the most energy?

In the preparation process from antimony ore to antimony trioxide powder, the high-temperature reduction smelting link has the highest energy consumption, which is related to many factors.

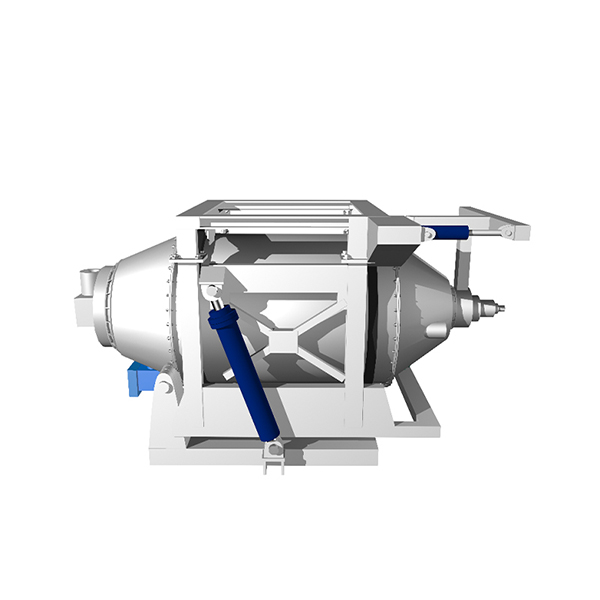

First, the reaction conditions are harsh. High-temperature reduction smelting needs to be carried out at about 1200°C. As the main equipment, the rotary furnace needs to consume a lot of electricity or coal, natural gas and other fuels to reach and stabilize this temperature, whether it is electric heating or fuel combustion heating. In addition, in order to ensure uniform temperature in the furnace, a complex temperature control system is required to further increase energy consumption.

Second, the reaction process consumes energy. The reducing agent added in the reaction reacts with antimony oxide to reduce antimony. This process requires energy to break chemical bonds and promote the reaction. This part of energy is input in the form of heat energy, which increases energy consumption.

Third, the reaction lasts for a long time. In order to ensure that antimony oxide is fully reduced and produce qualified crude antimony, the ore needs to react in the rotary furnace for a long time, which leads to continuous energy consumption and high energy consumption in this link.

In contrast, the energy consumption of other links is relatively low. Although the high-temperature desulfurization of antimony ore in the rotary furnace needs to be heated to 800-1000℃, the reaction time is short and part of the heat can be recovered; electrolytic refining uses electric energy to dissolve and precipitate antimony, with high energy conversion efficiency, and can optimize parameters to reduce energy consumption; when preparing antimony trioxide powder by high-temperature evaporation oxidation, the reaction system is small, and part of the heat can be reused using waste heat recovery technology.

In summary, the high-temperature reduction smelting link is the link with the highest energy consumption in the process from antimony ore to antimony trioxide powder.