NEWS&EVENTS

Home > News&Events > Company news > Flue gas treatment equipment helps rotary furnace smelting antimony ore

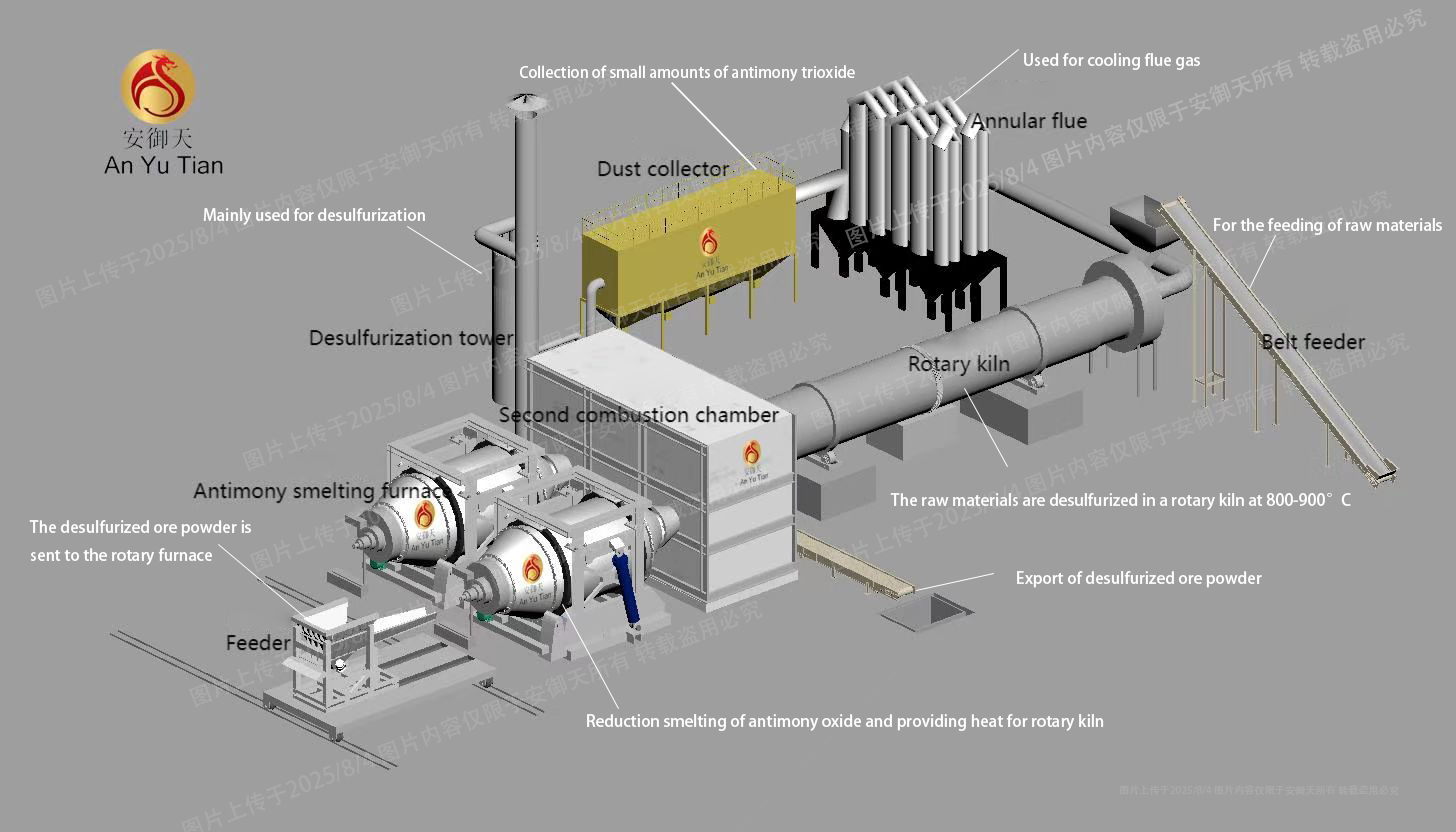

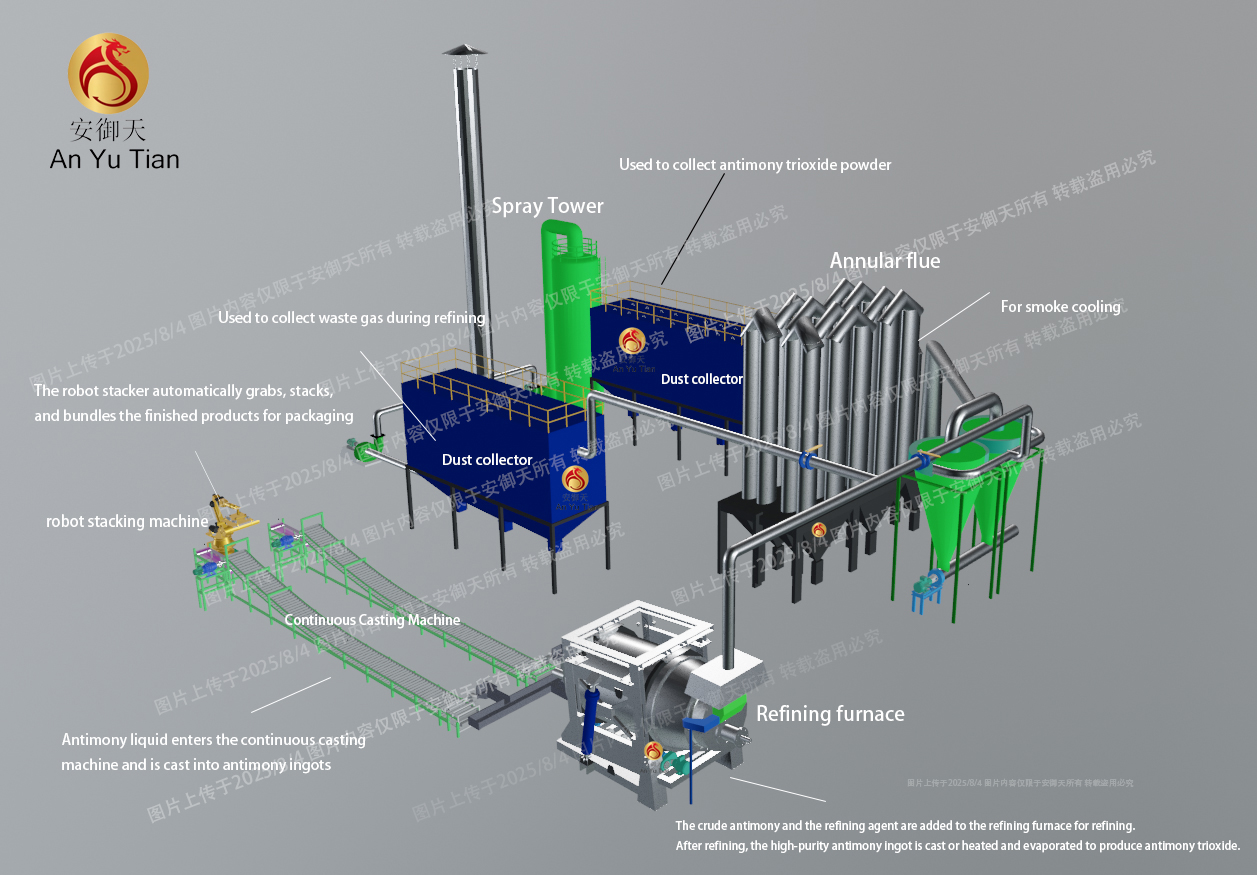

During the process of processing antimony ore in a rotary furnace, the flue gas generated needs to undergo a series of treatments to meet environmental emission requirements. This process is inseparable from the coordinated cooperation of equipment such as annular flues, dust collectors, and desulfurization towers.

Rotary furnace smelting produces high-temperature flue gas. Directly entering subsequent processing equipment, this flue gas can cause serious damage. Therefore, the high-temperature flue gas first enters a ring flue for initial cooling. The ring flue's rational structural design allows the flue gas to flow in a circuitous manner, exchanging heat with the surrounding cooling medium, effectively reducing the flue gas temperature and ensuring the safe operation of subsequent equipment.

After initial cooling, the flue gas enters the dust collector. During the antimony ore smelting process, the flue gas carries a small amount of valuable antimony trioxide and a large amount of dust. The dust collector separates the dust and antimony trioxide from the flue gas using principles such as physical filtration or electrostatic adsorption. The recovered antimony trioxide can be reused, improving resource utilization. Furthermore, after removing most of the dust, the flue gas is cleaner, reducing the processing burden on subsequent equipment.

Finally, the flue gas enters the desulfurization tower for desulfurization. Flue gas from antimony ore smelting typically contains harmful substances such as sulfur dioxide, which, if discharged directly, would cause serious atmospheric pollution. The desulfurization tower uses specialized desulfurization processes, such as limestone-gypsum wet desulfurization, to convert sulfur dioxide in the flue gas into harmless substances such as sulfates, thereby removing harmful gases and ensuring that the flue gas meets environmental emission standards.

Reasonable pipeline connections and airflow control are used between the flue gas treatment equipment to ensure smooth flow of flue gas, forming a complete and efficient flue gas treatment system and achieving environmentally friendly emissions during the antimony ore smelting process.