NEWS&EVENTS

Home > News&Events > Company news > How to ensure the quality of crude antimony metal smelted in rotary furnace

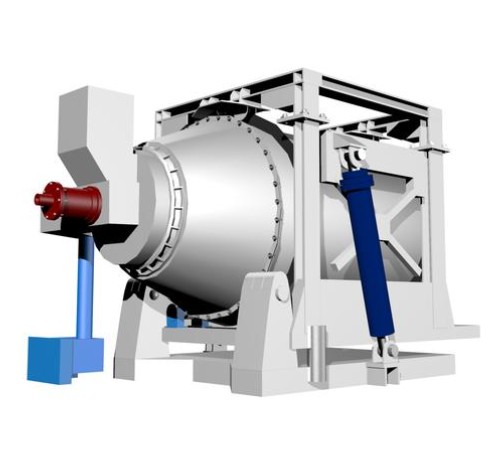

In the field of crude antimony metal smelting, the rotary furnace is a core piece of equipment. Precise control of its operating parameters is directly related to the purity and quality stability of crude antimony. As a rotary furnace manufacturer, we are fully aware of the importance of this critical link and are committed to providing customers with scientific and effective parameter control solutions.

Temperature is the primary factor affecting crude antimony quality. If the temperature is too low, the reaction will be incomplete, antimony recovery will be significantly reduced, and impurities will be difficult to completely remove. If the temperature is too high, antimony volatilization will increase and may cause impurities to form alloys with antimony, reducing purity. Therefore, our rotary furnaces are equipped with advanced temperature monitoring and control systems. These systems accurately determine the optimal temperature range based on ore properties and smelting processes, and adjust the temperature in real time to ensure the ideal temperature is always maintained.

The furnace atmosphere is equally important. A suitable reducing atmosphere acts as a protective shield against antimony oxidation. By adjusting ventilation and reducing agent dosage, we can maintain a slightly reduced state within the furnace, safeguarding the purity of the antimony.

Controlling reaction time is also crucial. Insufficient reaction time prevents the complete reaction and separation of impurities; excessive reaction time increases energy consumption and equipment wear. We consider factors such as ore size, composition, and rotary kiln speed to determine the optimal material residence time for our customers, ensuring a thorough and efficient reaction.

We also recommend that customers regularly test the quality of their crude antimony metal and adjust operating parameters based on the test results. We not only provide high-quality rotary furnace equipment, but also offer comprehensive technical support and after-sales service. Working hand in hand with our customers, we ensure that crude antimony metal maintains high purity and consistent quality, helping them stand out in the market.