In actual production, precise control of the rotary kiln temperature is crucial to ensuring the desulfurization effect and not affecting subsequent smelting. A multi-level temperature monitoring and control system is usually used.

First, multiple high-precision thermocouple temperature sensors are installed at key locations such as the feed, middle, and discharge ends of the rotary kiln to capture temperature changes in each area in real time, comprehensively understand the temperature distribution, and promptly detect anomalies. For example, if the feed temperature is low, the ore will not be fully preheated, affecting the desulfurization reaction; if the discharge temperature is high, the ore powder will easily over-sinter, increasing the difficulty of subsequent processing.

After acquiring the data, it is transmitted to the central control system, which acts as an "intelligent brain" and uses advanced algorithms to analyze it in real time, determining the temperature status based on preset ranges and process requirements. If there is any deviation, it immediately commands the burner to adjust the fuel supply and air flow, precisely regulating combustion intensity and stabilizing temperature.

Experienced operators are also crucial. They conduct regular inspections, observing visual indicators such as flames and material reactions, and then make comprehensive judgments based on system data. In special circumstances where the automatic system is insufficient, they can manually adjust parameters to ensure the appropriate temperature.

In addition, the rotary kiln is regularly thermally calibrated to evaluate indicators such as heat transfer efficiency and temperature uniformity, optimize and adjust the temperature control system, and calibrate and maintain temperature measurement equipment to ensure accurate and reliable data.

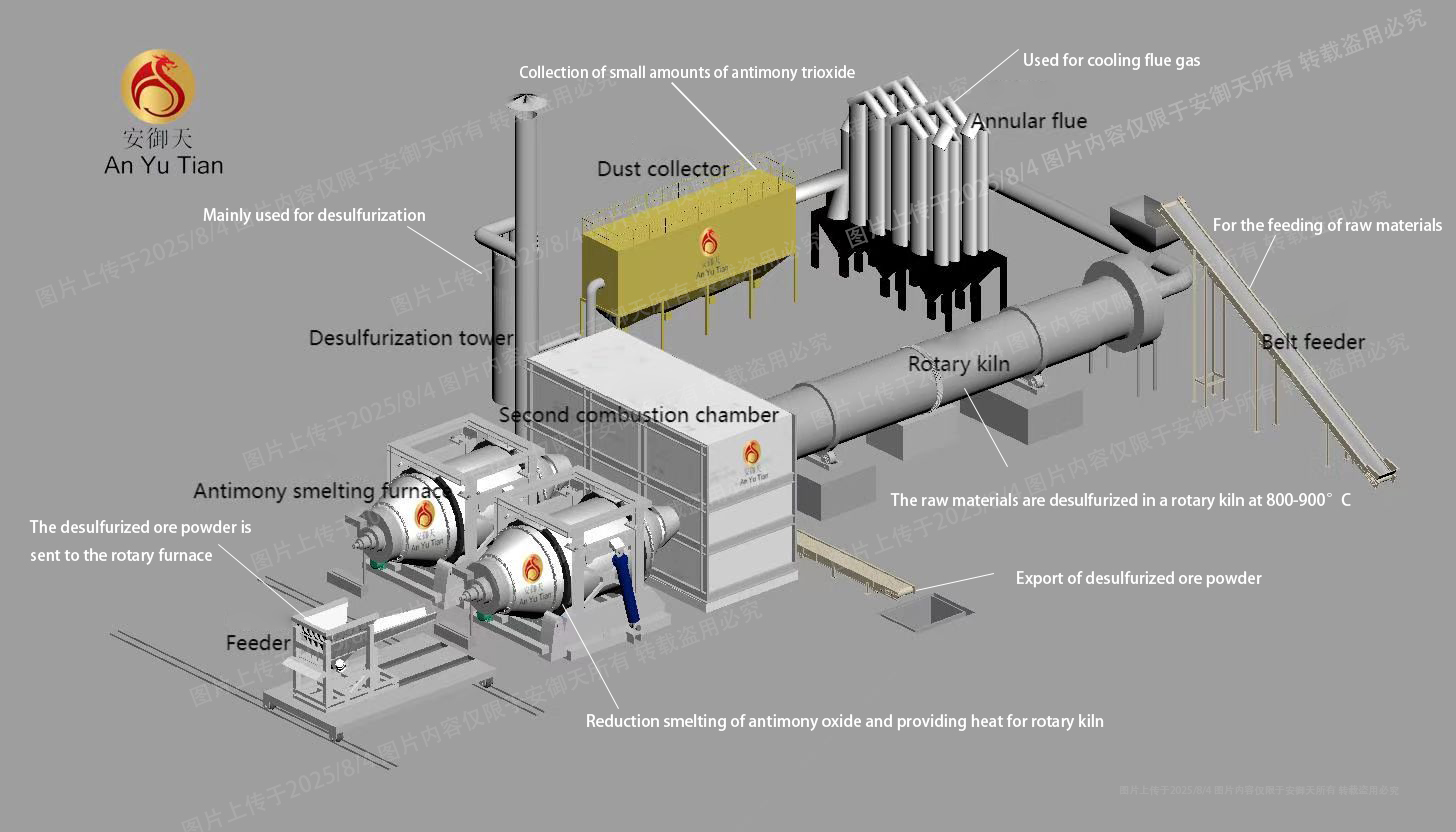

Through these meticulous measures, the temperature of the rotary kiln can be kept stable at 800-900℃, allowing the sulfur element to be fully oxidized and volatilized, achieving efficient desulfurization. It also creates good conditions for subsequent high-temperature reduction smelting, ensures a smooth process flow, and produces high-quality antimony ingots and antimony trioxide products.