NEWS&EVENTS

Home > News&Events > Company news > Importance of uniform temperature distribution in antimony rotary furnace

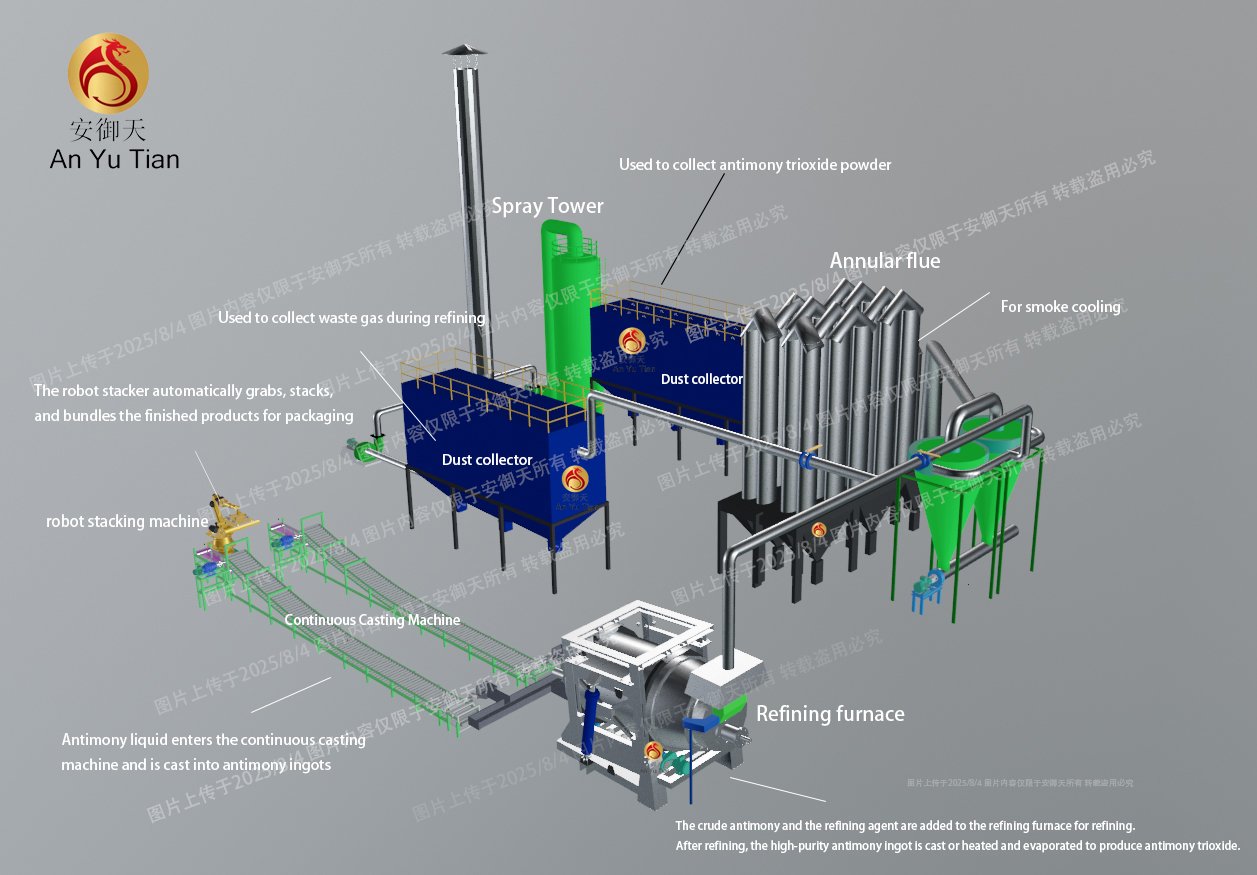

When producing antimony ingots and antimony trioxide from antimony ore, temperature uniformity within the antimony rotary furnace is a key factor affecting smelting results and product quality.

To achieve precise temperature control and uniform distribution, the rotary furnace utilizes a multi-zone heating structure. Burners are arranged along the furnace axis to provide heat in zones, creating a heat gradient. Combined with furnace rotation, the material tumbles, ensuring continuous heat absorption by the ore powder and preventing localized overheating or underheating.

Temperature uniformity also relies on an advanced automated control system. Temperature sensors are located at various locations within the furnace, collecting real-time data and feeding it back to a central control console. The system then adjusts the gas flow and air volume ratio of the burners in each zone to maintain a temperature differential within ±10°C, improving smelting efficiency and reducing issues such as excessive sulfur content in crude antimony metal.

The matching of the furnace rotation speed and the material fill rate is also crucial. Excessively fast rotation speeds can cause the material to slide against the wall, reducing heat transfer efficiency; excessively slow rotation speeds can cause material accumulation. In actual operation, technicians will dynamically adjust the rotation speed according to the ore conditions, controlling it at 0.5-2 rpm, while precisely controlling the material filling rate at 15%-20% to ensure sufficient heat penetration.

In addition, the rotary kiln introduces a flue gas waste heat recovery device, and the high-temperature flue gas transfers heat to the combustion air through the heat exchanger, improving combustion efficiency, reducing heat loss, and reducing overall energy consumption by more than 15%.

Through multi-dimensional and refined temperature control methods, the antimony rotary furnace achieves precise control of the temperature field, providing guarantees for stable product output and high-purity preparation. The pursuit of temperature uniformity is the core competitiveness of modern antimony smelting technology.