NEWS&EVENTS

Home > News&Events > Company news > Measures to solve abnormal pressure in antimony rotary furnace during operation

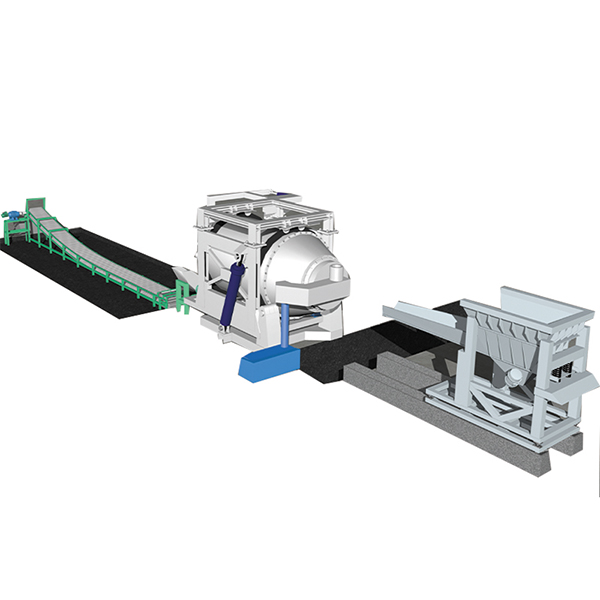

During actual operation, antimony rotary furnaces can sometimes experience abnormal pressures, impacting process stability and product quality, and even posing safety risks. If abnormal pressure is detected, operators must promptly implement emergency measures:

First, immediately stop adding new ore powder. Abnormal pressure may be caused by a vigorous reaction within the furnace or excessive addition; continued addition will only exacerbate the situation. Operators can precisely cut off the raw material supply by controlling the belt conveyor and feeder.

Second, quickly inspect the ventilation system. Poor ventilation is commonly caused by blocked pipes or fan failure. Operators should inspect the pipes for foreign objects and clean them promptly. They should also check the fan's operating status. If it fails, activate backup equipment to restore ventilation and regulate pressure.

Also, closely monitor temperature fluctuations. Abnormal pressure is closely related to temperature. Operators should monitor the temperature monitoring instrument. If the temperature is too high, reduce the heating device power. If the temperature is too low, inspect the heating system and increase the heat supply to maintain a suitable temperature to assist in pressure recovery.

In addition, verify the pressure monitoring equipment to ensure accurate readings. If any problems are found, repair or replace them immediately, and consider other parameters for a comprehensive assessment. If the pressure does not return to normal after initial treatment, immediately notify professional maintenance and process technicians for further investigation. Maintenance personnel should check the furnace structure and sealing devices, while process technicians should analyze whether there are other links related to the problem.

It is strictly forbidden to resume production without authorization before the problem is completely resolved. After professional personnel confirm that all parameters are normal and the equipment has no hidden dangers, restart the rotary kiln equipment according to the prescribed procedures and resume the production process to reduce the impact of abnormal pressure on production and ensure safety and stability.