NEWS&EVENTS

As an antimony rotary furnace manufacturer, we are well aware of the importance of antimony smelting furnaces to antimony ore processing companies. It is related to production efficiency, product quality and cost control.

The first step in selecting a rotary furnace is to clearly define production capacity targets. Companies should calculate daily, monthly, and annual production targets based on market demand, order size, and development plans, using this as the core basis for selection. Small-scale companies processing dozens of tons of antimony ore daily can choose compact, simple rotary furnaces, which require minimal space, require low investment, and are easy to operate and maintain, meeting their capital and production needs. Medium- and large-scale companies processing hundreds or even thousands of tons of antimony ore daily require large, high-efficiency rotary furnaces with advanced heating systems and optimized furnace structures. These furnaces enable rapid and uniform high-temperature reduction and smelting of ore, while also focusing on energy recycling to reduce production costs.

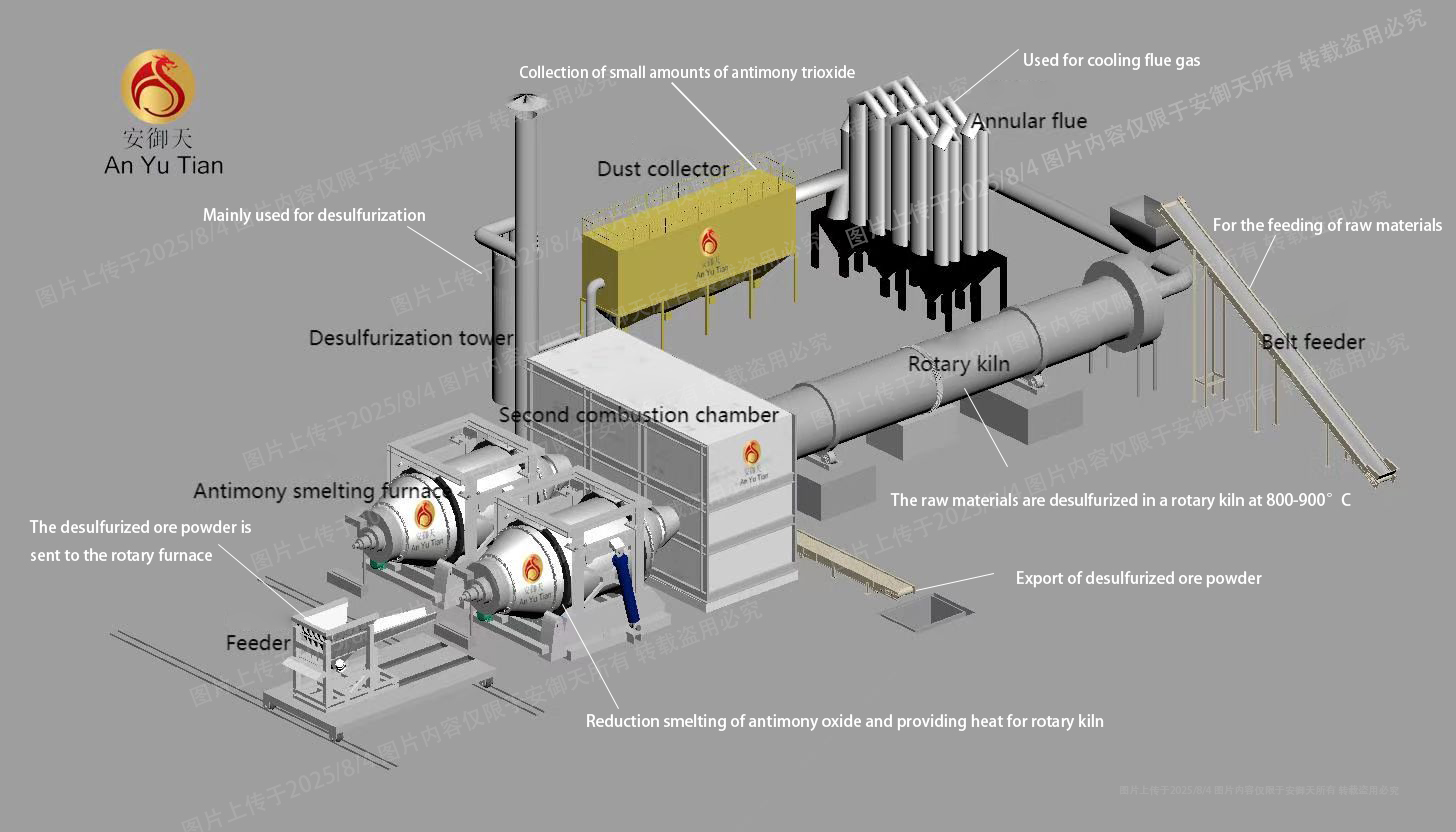

Material properties also cannot be ignored. Antimony ore composition, particle size, and humidity affect smelting results and equipment stability. If the ore has a high sulfur content, a rotary kiln with efficient desulfurization should be selected. If the particle size is uneven, the feed system must be adaptable to ensure uniform feeding.

Equipment reliability and ease of maintenance are equally critical. We use high-quality materials and strictly control manufacturing processes and quality to ensure long-term stable operation in harsh environments. Furthermore, easy-to-remove and replace parts, clear structure, and comprehensive maintenance manuals shorten repair time and reduce costs.

We also customize solutions based on your site, energy supply, and environmental requirements. For limited space, we choose a compact and strategically laid out design; we select heating methods based on energy sources; and we strictly adhere to environmental standards and equip you with advanced environmental equipment to achieve sustainable production. We consider all aspects to create the most suitable antimony rotary furnace solution for your business.