NEWS&EVENTS

Home > News&Events > Company news > How to optimize electrolytic equipment to extract high-purity antimony

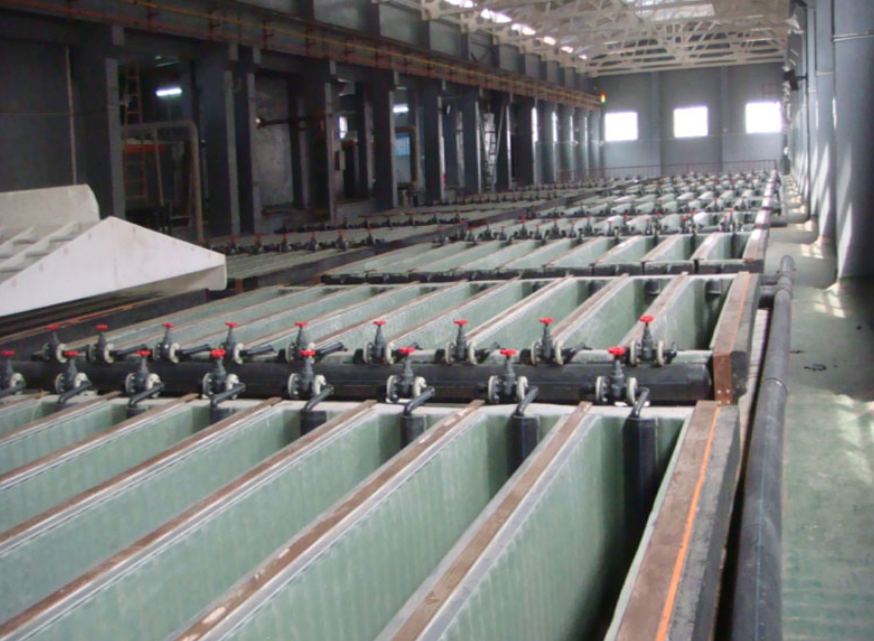

In the field of metal extraction, high-purity antimony, due to its unique physical and chemical properties, has irreplaceable applications in numerous high-tech industries, such as electronics and semiconductors. As a key technology for extracting high-purity antimony, electrolysis equipment optimization is crucial to improving extraction results, with optimizing the electrolyte circulation system being a key step.

During operation, conventional electrolysis equipment often experiences uneven distribution of electrolyte composition and temperature. This can lead to severe concentration polarization, whereby the electrolyte concentration near the electrode surface differs from that of the bulk solution, disrupting the normal electrochemical reaction process. This interference not only destabilizes the deposition process but also reduces current efficiency, extending production cycles and increasing energy consumption. It also makes it easier for impurities to enter the deposited antimony, compromising product purity.

Optimizing electrolyte circulation using a forced circulation system can effectively address these issues. Leveraging a powerful power unit, the forced circulation system accelerates the flow of electrolyte within the electrolytic cell, rapidly achieving a uniform electrolyte composition and temperature. This uniform electrolyte environment significantly reduces concentration polarization, providing stable conditions for the electrochemical reaction and enabling a smooth and orderly deposition process.

Under a stable environment, current can be used more efficiently to deposit antimony, reducing energy loss due to side reactions and electrode polarization, thereby significantly improving current efficiency. Furthermore, a stable deposition process facilitates the formation of a dense, high-purity antimony deposit, effectively preventing impurities from entering and improving product purity.

In short, by optimizing the electrolyte circulation system and adopting forced circulation, the electrolytic equipment can be made more efficient and stable when extracting high-purity antimony, providing strong guarantees for the large-scale, high-quality production of high-purity antimony and promoting the sustainable development of related high-tech industries.