NEWS&EVENTS

Home > News&Events > Company news > Gas-fired rotary furnace smelting: a key process for extracting copper from sulfide ores

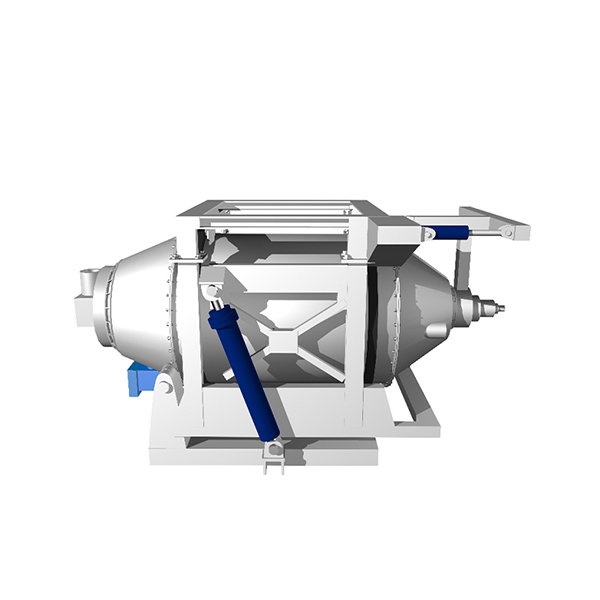

As a vital industrial metal, copper extraction technology has always garnered significant attention. The rotary furnace smelting process for extracting copper from copper sulfide ores is a highly efficient and widely used modern pyrometallurgical technique. Its core focus is on enriching copper and separating impurities through high-temperature oxidation reactions.

Smelting is the core of this process. First, copper concentrate is fed into a flash furnace or smelting furnace, where it is treated at temperatures of approximately 1200°C. This is an intense oxidation process: air or oxygen is introduced into the furnace, causing impurities such as iron and sulfur in the ore to oxidize. The sulfur is oxidized into sulfur dioxide (SO₂) gas, which is not simply waste but a valuable chemical raw material that can be recycled to produce sulfuric acid, achieving comprehensive resource utilization.

At the same time, iron is oxidized to ferrous oxide (FeO). To effectively separate this, the flux of silica (SiO₂) is added. The ferrous oxide and silica react to form a slag primarily composed of ferrous silicate (FeSiO₃). This slag has a low density and floats to the surface of the melt pool after melting, allowing it to be easily separated and discarded, thus removing a significant amount of iron impurities.

After the oxidation and slagging processes described above, the primary product remaining at the bottom of the furnace is an intermediate product called "matte." Matte is a molten mixture of copper and ferrous sulfide, with a chemical composition of Cu₂S·FeS. The copper content is significantly enriched at this stage, reaching approximately 50% to 70%. It is not pure copper, but rather provides high-grade raw material for the subsequent converting process.

The rotary furnace smelting process is known for its continuous operation, high efficiency, low energy consumption and good environmental benefits (such as sulfur recovery). It is an indispensable key technology in modern copper smelting. It successfully concentrates and purifies the copper in the ore step by step, laying a solid foundation for the ultimate production of refined copper.