NEWS&EVENTS

Home > News&Events > Company news > Rotary furnace and rotary kiln: efficient synergy of energy recycling

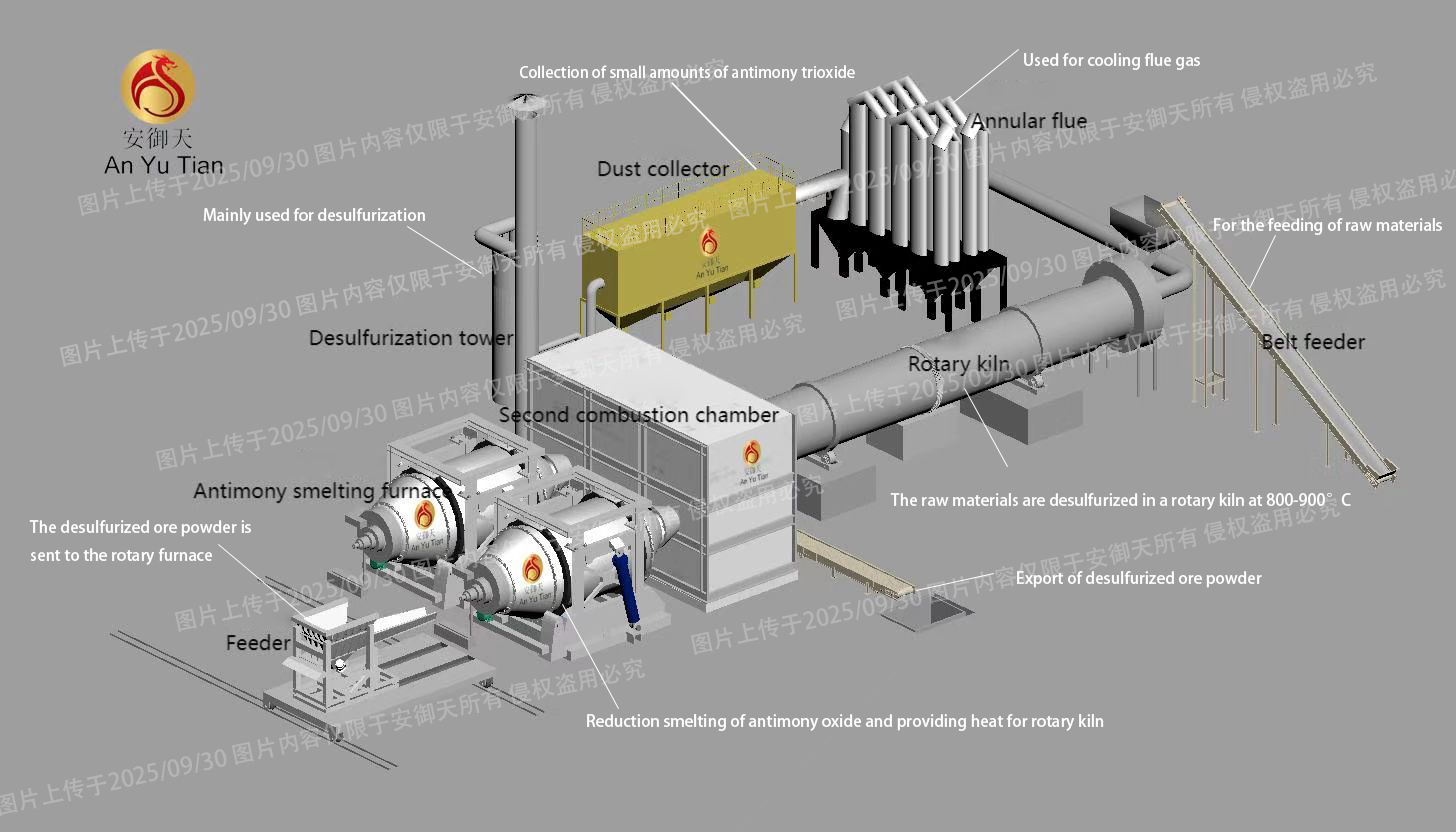

In the field of industrial production, the coordinated operation of rotary kilns and rotary furnaces constitutes an ingenious and efficient energy recycling system, in which the rotary kiln plays the key task of providing heat for the rotary kiln.

During the smelting process, rotary furnaces produce large amounts of high-temperature flue gas. This flue gas is not simply waste, but a valuable resource containing enormous amounts of thermal energy. To achieve energy recycling, the system cleverly directs this high-temperature flue gas to the rotary kiln, where it uses the heat energy carried by the flue gas to heat the kiln. This allows heat energy that would otherwise be wasted to be reused, creating an efficient internal energy cycle.

This energy recycling approach brings significant benefits to the entire production system. First, it significantly reduces energy consumption. By fully utilizing the waste heat generated within the system, reliance on external fuels is reduced. Previously, heating the rotary kiln required significant amounts of external fuels such as coal and natural gas. Now, with the high-temperature flue gas from the rotary kiln, this use of external fuels has been significantly reduced, directly saving production costs and improving the company's economic benefits.

Secondly, it excels in improving efficiency. This system achieves a cascaded utilization of thermal energy: high-temperature flue gas first performs a smelting function in the rotary furnace, and the remaining heat energy is then used to heat the rotary kiln. This ensures that thermal energy is rationally distributed and fully utilized across different stages. This not only optimizes the thermal balance of the entire system but also improves energy efficiency, making the production process more efficient and smoother.

The energy recycling between the rotary furnace and the rotary kiln is a model of energy conservation and efficiency improvement in industrial production, and provides a useful reference for sustainable development.