NEWS&EVENTS

Home > News&Events > Company news > Generation and Treatment of Anode Slime in Antimony Electrolytic Refining

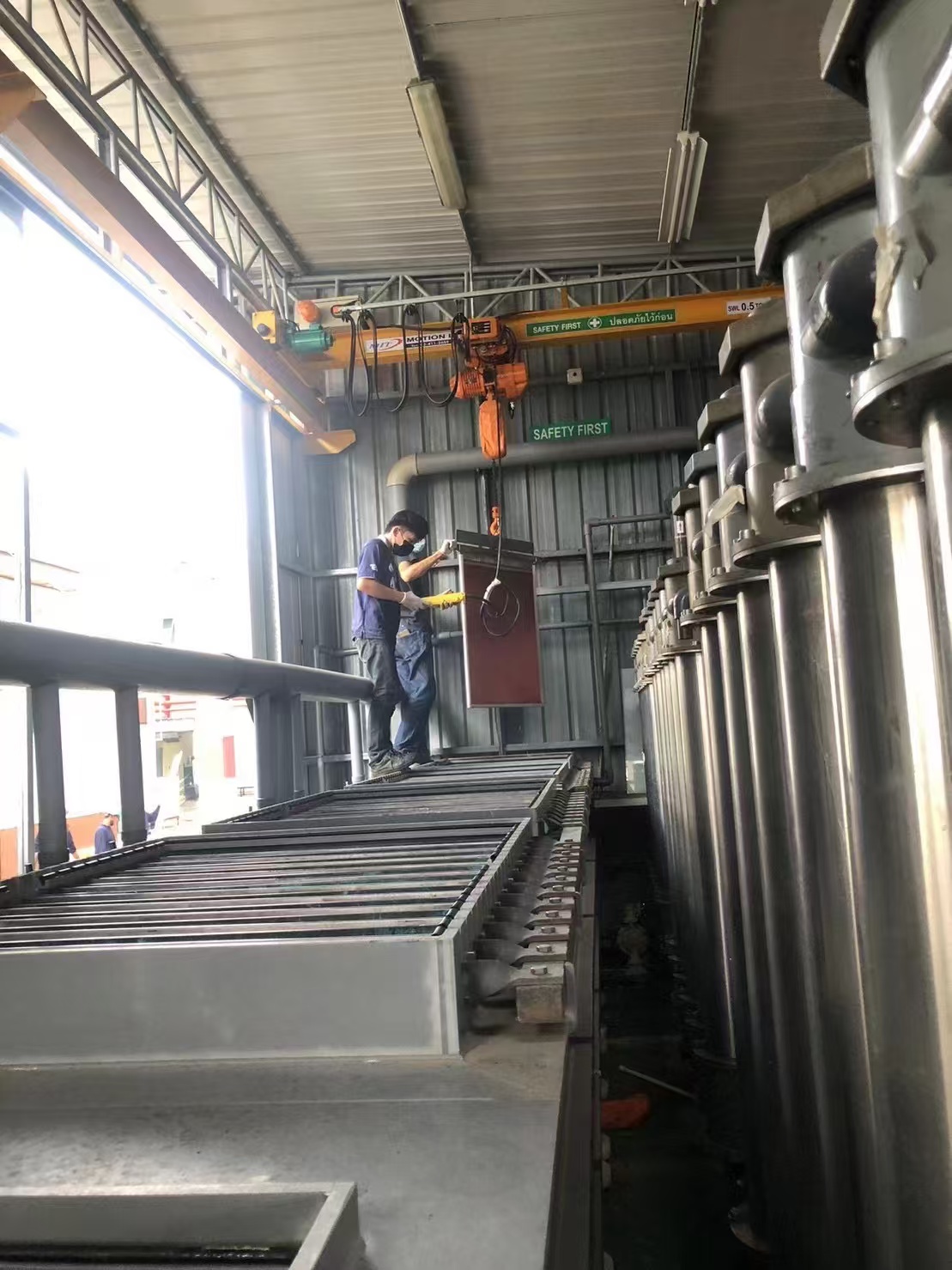

In the electrolytic cell system of antimony electrorefining, the formation of anode slime is a typical phenomenon based on electrochemical principles. When the electrolysis process begins, the crude antimony anode plate becomes an active site for electrochemical reactions. Antimony, the main component of the anode, undergoes electrochemical dissolution under the action of current, steadily entering the electrolyte in ionic form and participating in the subsequent electrochemical cycle.

However, the crude antimony anode plate contains some unique "members." Precious metals, such as gold and silver, are less active than antimony metal. Their chemical properties are extremely stable, making it difficult for them to lose electrons and dissolve under electrolytic conditions. Furthermore, there are some insoluble compounds that also lack the ability to dissolve in the electrolyte. Unlike antimony, these substances cannot enter the electrolyte and must remain in solid form. As the electrolysis reaction continues, these substances gradually flake off the anode surface or slowly settle on the bottom of the anode, eventually converging to form "anode mud."

Treatment of anode mud is of vital importance. Anode mud contains a large amount of valuable metals, especially precious metals such as gold and silver, which have extremely high economic value. Using specialized technologies to extract and separate anode mud enables the secondary utilization and comprehensive development of this resource.

This process profoundly embodies the advanced concept of "green metallurgy" or "waste-free metallurgy." In the modern metallurgical industry, it advocates a circular economy model that fully exploits every valuable element in ore, maximizing resource utilization. At the same time, it effectively reduces waste generation and emissions, minimizing negative environmental impacts. This not only improves economic efficiency but also drives the metallurgical industry toward a more environmentally friendly and sustainable development.