NEWS&EVENTS

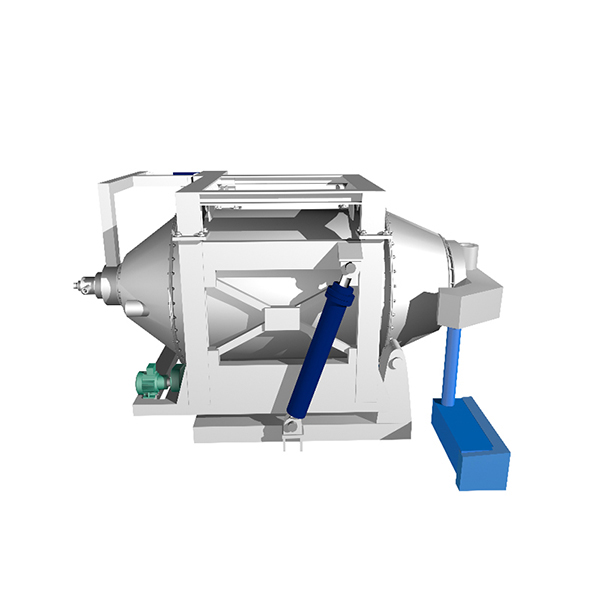

Home > News&Events > Company news > Why is it important to control the "atmosphere" in the antimony rotary furnace?

The reason why it is extremely important to control the "atmosphere" in the antimony rotary furnace is that it has a decisive influence on the antimony reduction smelting process and the quality of the final product.

+

+

Antimony reduction smelting is a chemical reaction process with stringent environmental requirements. It must be carried out in a reducing atmosphere, that is, an oxygen-deficient environment. In this reducing atmosphere, antimony oxides can be smoothly reduced to metallic antimony by the reducing agent, thus achieving efficient smelting.

However, if the antimony rotary furnace is not tightly sealed, outside air can enter. This entry of air instantly disrupts the carefully cultivated reducing atmosphere within the furnace, introducing a large amount of oxygen. At this point, the already reduced metallic antimony reacts readily with oxygen, becoming oxidized again to form antimony trioxide. This newly formed antimony trioxide is then discharged from the furnace along with the flue gases, resulting in significant loss of antimony.

From the perspective of production efficiency, the loss of antimony directly leads to a significant reduction in the direct recovery rate of crude antimony. This means that for the same amount of raw materials, the final crude antimony output is significantly reduced, greatly increasing production costs and reducing economic benefits.

From a product quality perspective, the oxygen content of crude antimony increases due to oxidation. Excessively high oxygen content alters the physical and chemical properties of crude antimony, leading to a decrease in key indicators such as purity, hardness, and ductility. This makes it impossible to meet the standards for high-quality antimony products, severely impacting the product's market competitiveness.

Therefore, strictly controlling the atmosphere in the antimony rotary furnace to ensure that it is always in a stable reducing state is the key to ensuring the smooth progress of antimony reduction smelting, improving production efficiency and enhancing product quality.