NEWS&EVENTS

Home > News&Events > Company news > Processing technology after purification and refining of crude antimony by slag formation

After crude antimony is purified and refined by the slag-making method, a series of subsequent processing steps are required to obtain high-quality products.

The first step is the stirring and settling process. After all the slag-forming operations are completed, the antimony liquid is thoroughly stirred and then allowed to stand for a period of time; this process is called "setting." Its purpose is to give the remaining tiny slag droplets sufficient time to float to the surface, while ensuring that the chemical reaction proceeds completely, further improving the purity of the antimony liquid.

Next, sampling and testing are conducted. A small amount of molten antimony is taken from the furnace, cast into small samples, and broken. The purity is determined by observing the fracture surface characteristics. Pure antimony exhibits a distinct "star-shaped radial" structure on the fracture surface, with a bright bluish-white color and a significant "antimony blue" sheen. If the fracture surface is dark, gray, or disordered, and lacks a star-shaped structure, it indicates the presence of impurities in the antimony.

If the test results are unqualified, the type of impurity must be determined based on the fracture characteristics, and then the corresponding slag-making steps must be repeated for supplementary refining until the purity of the antimony liquid meets the standard.

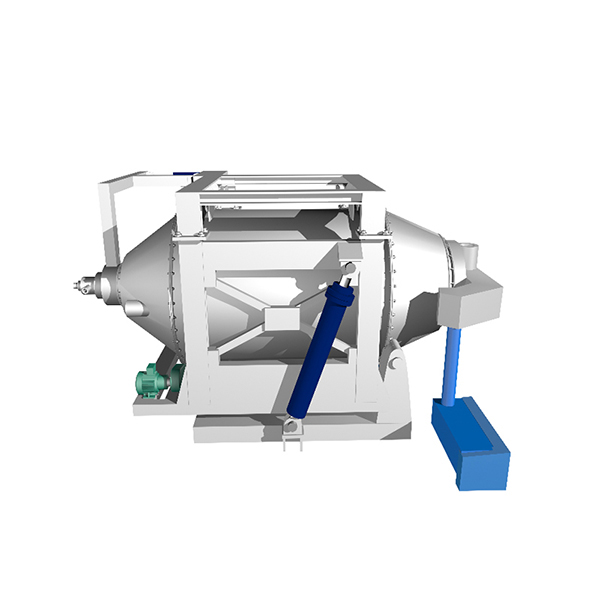

After the above purification process, high-purity liquid antimony is obtained, which has two main uses. First, it is used for ingot casting, where the molten antimony is poured into a continuous casting machine and cast into regular antimony ingots for easy storage and transportation. Second, it is used to produce antimony trioxide, where the molten antimony is transferred to an oxidation furnace. Through a series of operations including oxidation, volatilization, and baghouse dust collection, high-purity antimony trioxide is finally produced, which has wide applications in various industrial fields. The entire processing technology is interconnected, ensuring the quality of the refined antimony product.