NEWS&EVENTS

Home > News&Events > Company news > Why are efficient rotary furnaces crucial to the success of antimony smelting?

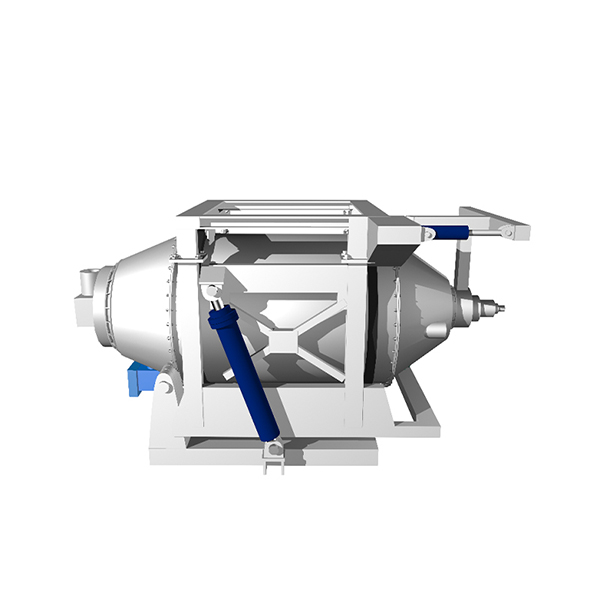

Why is an efficient rotary furnace crucial for successful antimony smelting? In the antimony smelting industry, the rotary furnace is a key piece of equipment and a technological cornerstone for cost reduction, efficiency improvement, and green development.

1. Process Synergy, Ensuring Production

Efficient smelting relies on smooth integration. The rotary kiln design is precisely matched with the rotary furnace, enabling continuous and stable feeding, avoiding temperature fluctuations and production interruptions caused by traditional intermittent feeding. This lays the foundation for efficient operation of the entire process, improving equipment utilization and capacity.

2. Core Smelting, High Efficiency and Energy Saving

In the high-temperature reduction smelting stage, the rotary kiln's unique rotating design and internal structure ensure sufficient contact between the material and the reducing agent, resulting in complete reaction, improved metal recovery rate, and reduced resource waste. Its thermal energy circulation design is the core of cost reduction; high-temperature flue gas is scientifically designed to provide heat to the rotary furnace, significantly reducing system energy consumption and fuel costs, and achieving energy reuse. The equipment uses a special refractory lining and an efficient thermal model, enabling long-term stable operation at 800-900°C, improving heat recovery efficiency.

3. Green Production, Environmental Protection and Profitability

Under environmental pressure, the rotary kiln empowers from the source. The reasonable furnace structure and temperature field control stabilize the flue gas composition and temperature, creating conditions for efficient recovery of antimony trioxide and desulfurization treatment. This helps companies meet environmental standards and also opens up new profit growth points through the recovery of high-value by-products.

Choosing a rotary furnace means choosing a comprehensive solution. We not only provide equipment but also integrate technology into design and service. Given the varying ore grades and product requirements, we invite you to communicate with our technical team to obtain customized optimization solutions and jointly embark on a new chapter of efficient and profitable antimony smelting.