NEWS&EVENTS

Home > News&Events > Company news > Analysis of Automated Equipment in Modern Copper Electrolysis Workshops

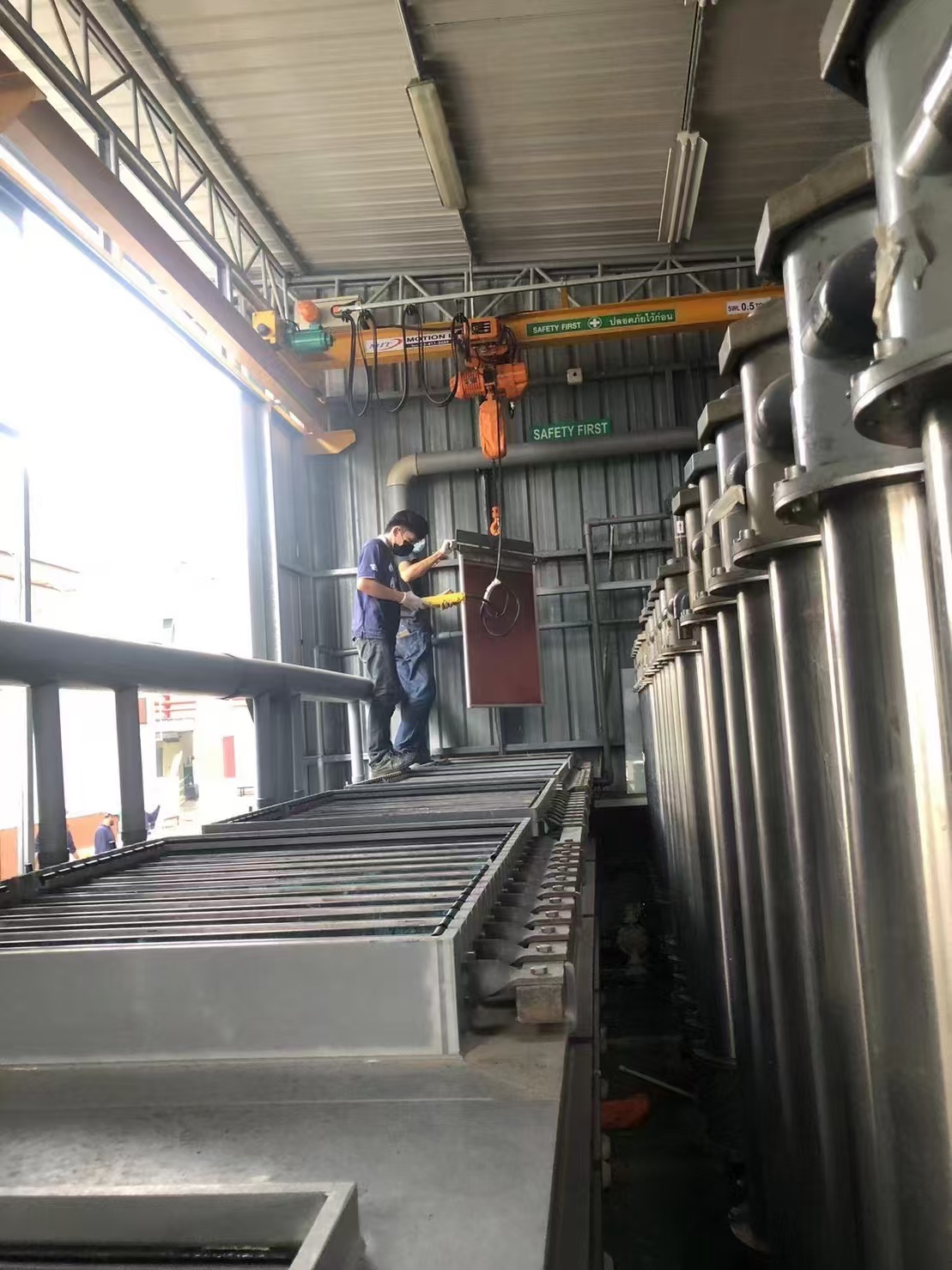

Modern large-scale copper electrolysis workshops integrate automated equipment and intelligent control systems to achieve fully automated operation of electrolytic cells, improving production efficiency, process stability, and operational safety. The core automated operations rely on the coordinated work of several key pieces of equipment:

The electrode handling unit is responsible for the automated processing of anode plates and starting sheets. Through specialized lifting devices, it achieves precise insertion of anode plates into the cells, regular replacement, and removal of residual anodes, as well as automatic arrangement and loading of starting sheets, replacing manual labor, reducing labor intensity, and ensuring consistent electrode spacing and good contact to stabilize the electrolysis process.

The cathode stripping unit is the core equipment for finished copper processing. After the deposition cycle, the mother plates carrying the cathode copper are transported to this unit, where the cathode copper is automatically stripped using vibration, pins, or gripping devices, followed by washing, weighing, stacking, and packaging. This achieves a high stripping rate and low damage rate, shortens the unloading time, and reduces the risk of human contact with corrosive electrolyte.

The automatic short-circuit detection and handling system ensures the efficient operation of the electrolytic cells. Sensors continuously monitor cell voltage and current distribution, automatically identifying abnormal conditions such as short circuits and triggering robotic arms or other mechanisms for repair, preventing energy waste and production losses.

The online electrolyte monitoring and automatic addition system is responsible for precise control of process parameters. It analyzes the electrolyte composition in real time and automatically replenishes chemicals and adjusts the temperature using metering pumps and valves to maintain optimal electrolysis conditions, ensuring uniform cathode copper quality and controllable impurities.

These automated copper electrolysis equipment are integrated and scheduled by a central control system, forming a continuous, precise, and reliable electrolysis production process, improving labor productivity, stabilizing technical indicators, and improving the workshop environment. This represents an important direction for the intelligent and green transformation of modern copper smelting.