NEWS&EVENTS

Home > News&Events > Company news > What is the main purpose of refining anode copper using the tilting rotary furnace method?

The core purpose of refining anode copper using a tilting rotary furnace is to transform crude copper into anode plates that meet the requirements of electrolytic refining. Its main functions include:

1. Impurity Removal

Through oxidation, slag formation, and volatilization reactions, harmful impurities such as sulfur, oxygen, arsenic, antimony, lead, and bismuth are removed from the crude copper, improving the purity of the molten copper.

2. Composition Adjustment

Controlling the oxygen content and other residual elements in the molten copper ensures that the chemical composition and physical properties of the anode plates meet the requirements of the electrolytic process.

3. Casting and Shaping

The refined molten copper is cast into anode plates with a regular shape and uniform thickness, ensuring uniform current distribution and stable anode dissolution during the electrolysis process.

4. Ensuring Electrolytic Efficiency

High-quality anode plates reduce problems such as passivation, short circuits, and abnormal anode sludge during the electrolysis process, thereby improving the quality of cathode copper, reducing energy consumption, and lowering costs.

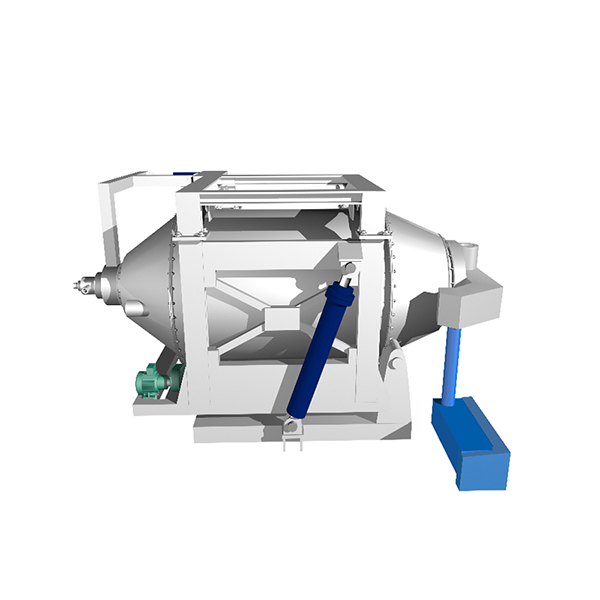

In summary, the tilting rotary furnace, as the core equipment for pyrometallurgical refining, directly determines the quality of the anode plates and is a crucial link in ensuring the efficient and stable connection between crude copper smelting and electrolytic refining.