NEWS&EVENTS

Home > News&Events > Company news > Refining process from crude antimony to antimony ingot and antimony trioxide

The rotary refining furnace is a continuous operation equipment used for smelting. Its furnace body is cylindrical and can rotate around a horizontal axis. This unique structure allows the materials in the furnace to be evenly heated and fully mixed during the rotation process.

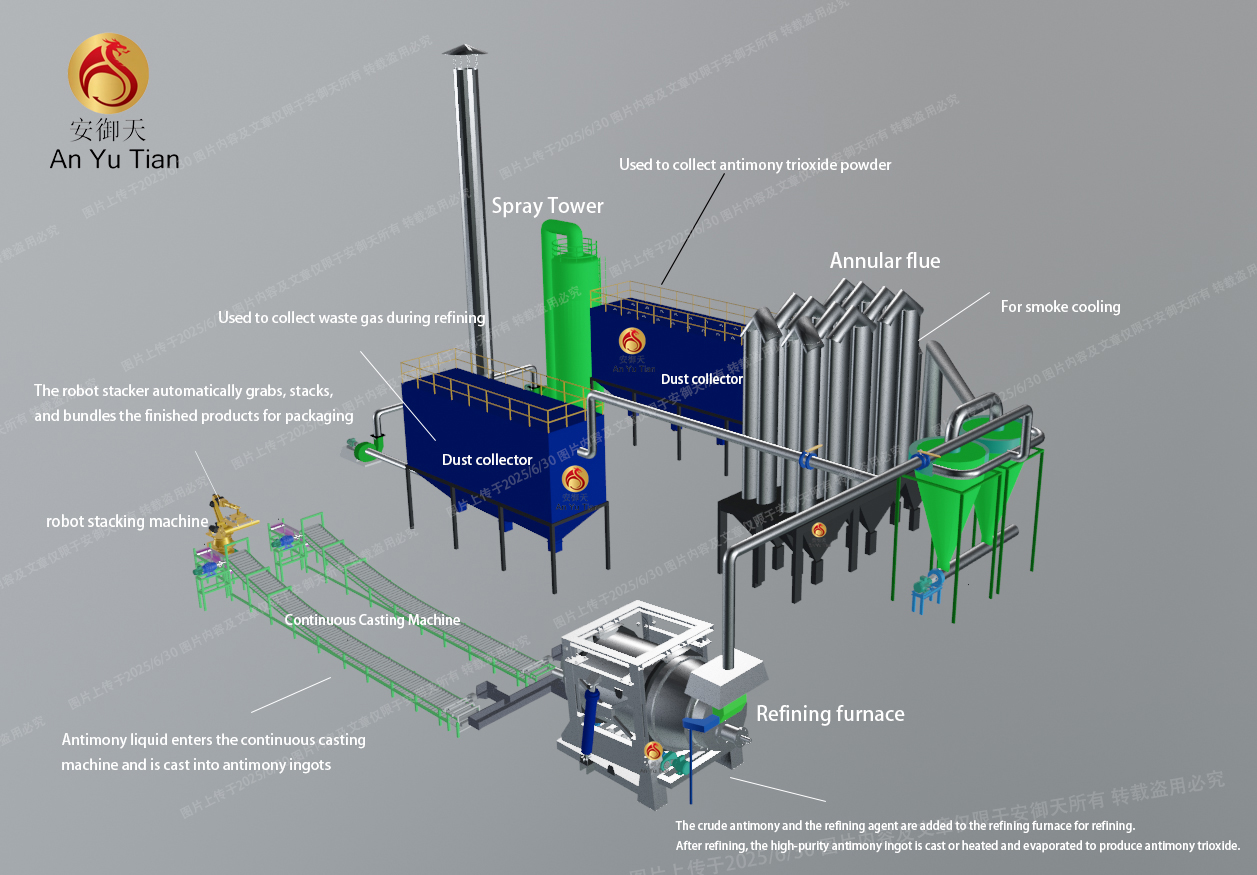

In the refining process from crude antimony to antimony ingots and antimony trioxide, the prepared crude antimony and refining agent must be loaded into the furnace in a specific proportion. Subsequently, the heating system of the rotary refining furnace is started to gradually increase the temperature in the furnace. When the temperature reaches the melting point of crude antimony, the crude antimony begins to melt and transform into liquid antimony. During this melting stage, the heating speed and the temperature in the furnace must be strictly controlled to prevent overheating or local overheating of the crude antimony, thereby ensuring that the smelting effect is not affected.

After the refining process is completed, the pure liquid antimony needs to be discharged from the rotary refining furnace and injected into the mold through the casting system, waiting for it to cool and solidify. During the casting process, the casting speed and temperature also need to be precisely controlled to avoid defects such as cracks or pores in the antimony liquid.

After cooling and solidification, refined antimony blocks need to undergo quality inspection, including chemical composition analysis and physical property testing. Only qualified refined antimony blocks will be packaged and stored for subsequent use or sale.

If high-purity antimony trioxide is to be produced, it is necessary to continue heating after refining to evaporate and oxidize the antimony. Under the high temperature conditions of the rotary refining furnace, antimony vapor reacts chemically with the injected oxidant to generate antimony trioxide gas. The gas enters the multi-stage dust removal system with the process airflow, first passes through the cyclone separator for primary purification, and then passes through the bag filter for fine collection, and finally obtains antimony trioxide powder products with uniform particle size distribution. The entire production process adopts closed negative pressure operation to ensure the high purity of the product, which fully meets the technical requirements of high-end application fields such as electronic grade.