NEWS&EVENTS

Home > News&Events > Company news > Advantages of slag formation in the pyrometallurgical process of antimony ore

In the pyrometallurgical process of antimony ore, slagging plays a crucial role, and its advantages are reflected in multiple key aspects.

Purification is a prominent advantage of slag making technology. During the smelting process, antimony ore inevitably contains various impurities such as iron, copper, lead, etc. The slag making process can generate stable slag by adding appropriate slag making agents and reacting chemically with these impurities. These slag materials have different densities from antimony metal melt and are layered under the action of gravity, selectively separating impurities into the slag and effectively improving the purity of antimony products, laying the foundation for subsequent high-quality applications.

In terms of antimony preservation, the slag making process has also achieved significant results. In high-temperature melting environments, the metal melt pool is prone to dispersion, causing loss of antimony metal. The slag making process can promote the polymerization of the metal melt pool, form a more concentrated metal phase, reduce the entrainment and volatilization loss of antimony metal in the slag, improve the recovery rate of antimony, and reduce production costs.

The environmental advantages cannot be ignored either. Antimony ore often contains harmful substances such as arsenic and cadmium, which can cause serious environmental pollution if not treated during the smelting process. The slag making process can stably solidify these harmful substances in the slag, reduce the risk of their volatilization and diffusion into the environment, achieve clean production, and meet modern environmental protection requirements.

In addition, the slag making process can also increase efficiency. The slag separated by slag making often contains other valuable metals, creating conditions for further recovery of these valuable metals and improving the comprehensive utilization rate of resources.

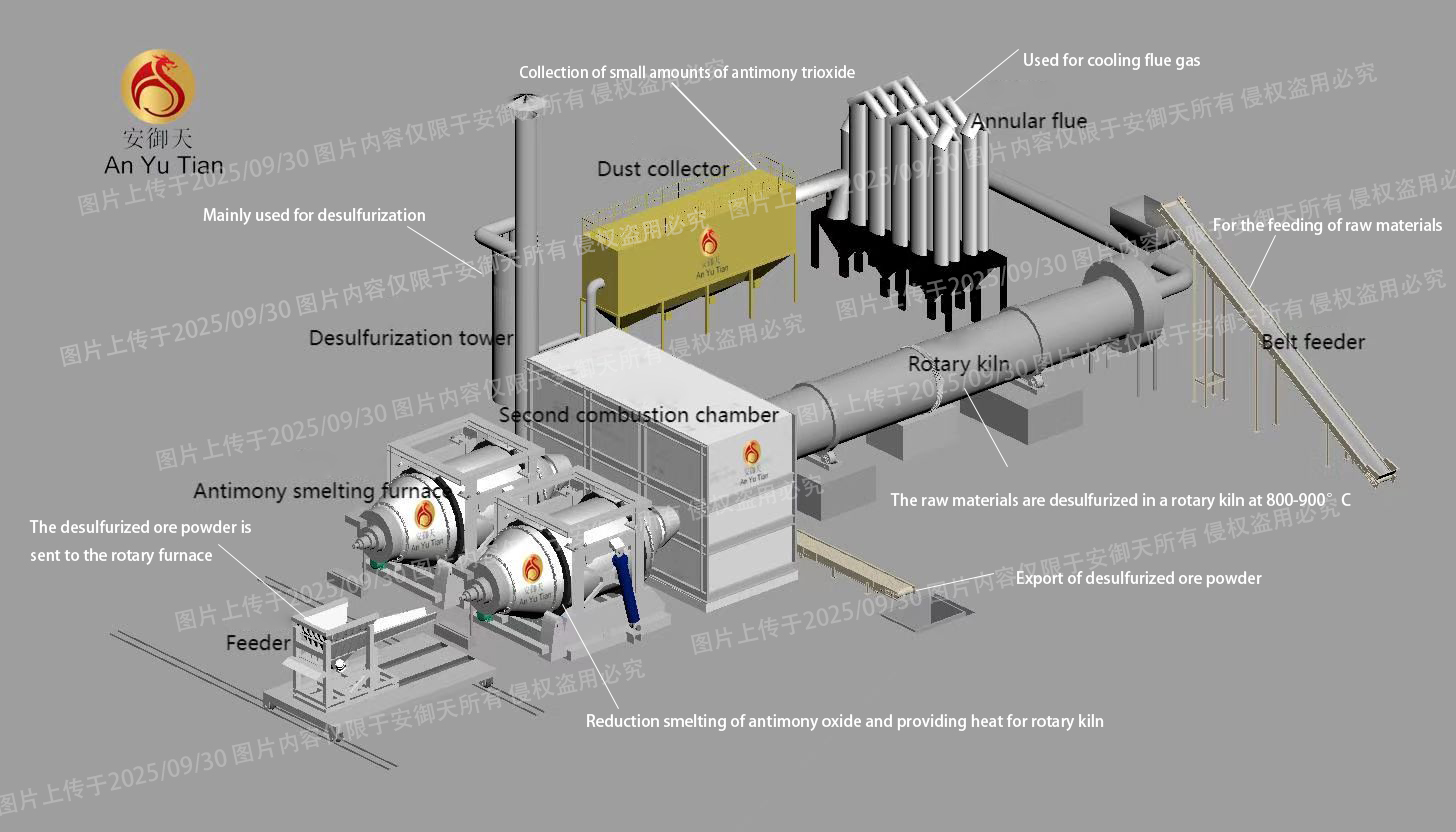

The precise coordination between the slag making method and core equipment such as rotary kilns, rotary furnaces, and refining furnaces enables the efficient, environmentally friendly, and economical operation of the entire pyrometallurgical antimony refining process, promoting the development of the antimony smelting industry towards a green and sustainable direction.