NEWS&EVENTS

The extraction of precious metals is a core process in the field of resource recycling. By relying on advanced equipment and process technology, the recovery rate and economic benefits can be significantly improved. The following provides a detailed explanation of the key process flow, taking into account the advantages of the equipment.

A. Preprocessing and dissociation

Pre treatment aims to fully expose precious metal minerals. Firstly, an efficient crusher is used for coarse crushing, which is designed to handle hard ores with high strength and low energy consumption. Subsequently, it enters the energy-saving ball mill for ultrafine grinding, which adopts an optimized transmission system with high grinding efficiency and uniform particle size distribution. The grading process is equipped with a grading cyclone to accurately separate qualified particles and remove mineral mud that affects subsequent processing, laying the foundation for efficient enrichment.

B. Enrichment of precious metals

Enrichment is the core of the recycling process. For coarse-grained minerals with high dissociation degree, re-election or flotation can be used. For fine-grained and impregnated precious metals, wet metallurgy is more efficient. In conventional cyanide leaching or environmentally friendly thiosulfate/thiourea leaching processes, efficient leaching agitation tanks can enhance mass transfer and ensure sufficient reaction; A dedicated inflation system provides a stable atmosphere for the oxidation process; After leaching, environmentally friendly washing equipment is used to achieve efficient solid-liquid separation and reduce the loss of precious metals. In addition, cutting-edge technologies such as bio metallurgy have provided new ideas for dealing with difficult resources.

C. Separation and Refining of Precious Metals

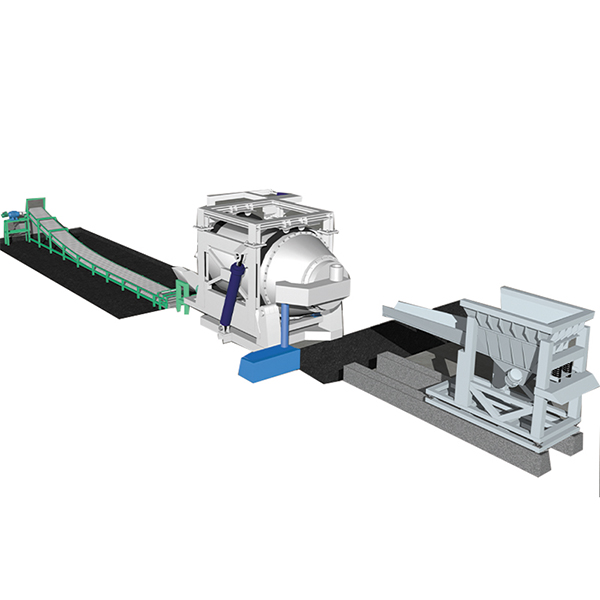

The recovery of precious metals from solutions is commonly achieved through activated carbon adsorption/desorption systems or resin adsorption processes targeting platinum and palladium, which have high adsorption capacity and thorough desorption. The gold loaded material is further refined by high-temperature electrolytic refining system or high-efficiency displacement reactor (such as zinc powder displacement) to extract the metal. For complex systems such as platinum group metals, precision solvent extraction devices can achieve highly selective separation, combined with high-temperature refining furnaces, to ultimately obtain high-purity products.

Relying on the above processes and customized equipment, precious metal extraction can achieve high efficiency, environmental protection, and maximum resource utilization, providing reliable technical support for various mineral resource projects.