NEWS&EVENTS

Home > News&Events > Company news > Reduction slag formation during the reduction smelting of antimony in a rotary furnace

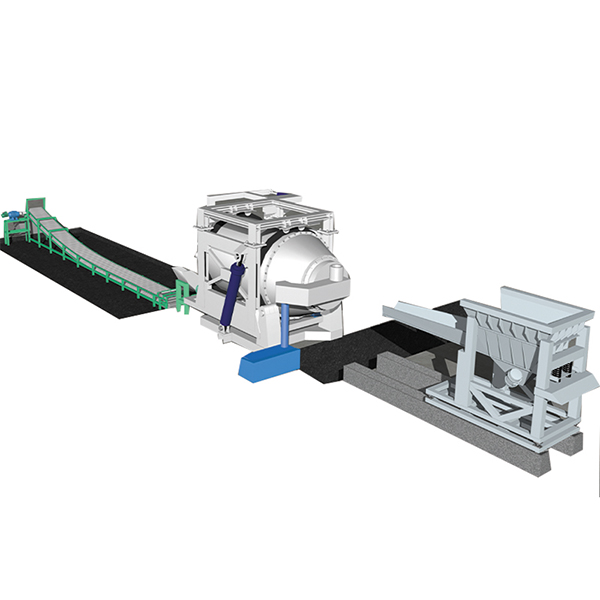

Rotary furnace reduction smelting is the core process of antimony extraction. At this stage, the application of slag making method plays a decisive role in improving metal recovery rate and product quality. The desulfurized antimony ore powder (mainly composed of antimony oxide) transported from the rotary kiln reacts with carbonaceous reducing agent in the rotary furnace and is reduced to crude antimony metal. To achieve efficient separation of impurities, it is necessary to add appropriate alkaline fluxes, such as soda ash (Na ₂ CO3) or lime (CaO), based on the composition of the gangue in the ore, which is mainly acidic oxides such as silicon dioxide (SiO ₂). Flux reacts with gangue to form slag, resulting in low melting point and good flowability sodium silicate or calcium silicate salt slag.

This slag making process plays multiple key roles: firstly, the slag can effectively dissolve and capture metal oxide impurities such as iron, copper, and lead in the ore, separating them from the molten crude antimony; Secondly, slag with good fluidity facilitates the aggregation and settling of metal antimony droplets, significantly reducing mechanical inclusions of antimony in the slag and thus improving the metal yield; In addition, the slag layer covering the surface of the metal melt can also form a protective barrier, suppress the volatilization of antimony and prevent it from being excessively oxidized.

After smelting is completed, the products in the furnace show clear layering: the lower layer is crude antimony obtained by reduction, and the upper layer is smelting slag rich in alkali metal silicates, often referred to as "antimony foam slag". It is worth noting that the slag still contains about 1% -4% antimony, so it needs to be further processed (such as slag reduction or combined metallurgical processes) to recover valuable metals and achieve full resource utilization. The entire process of reducing slag has significantly optimized the technical and economic indicators of antimony smelting through scientific formulation and regulation.