NEWS&EVENTS

Home > News&Events > Company news > Antimony converter is the core equipment that runs through the entire process

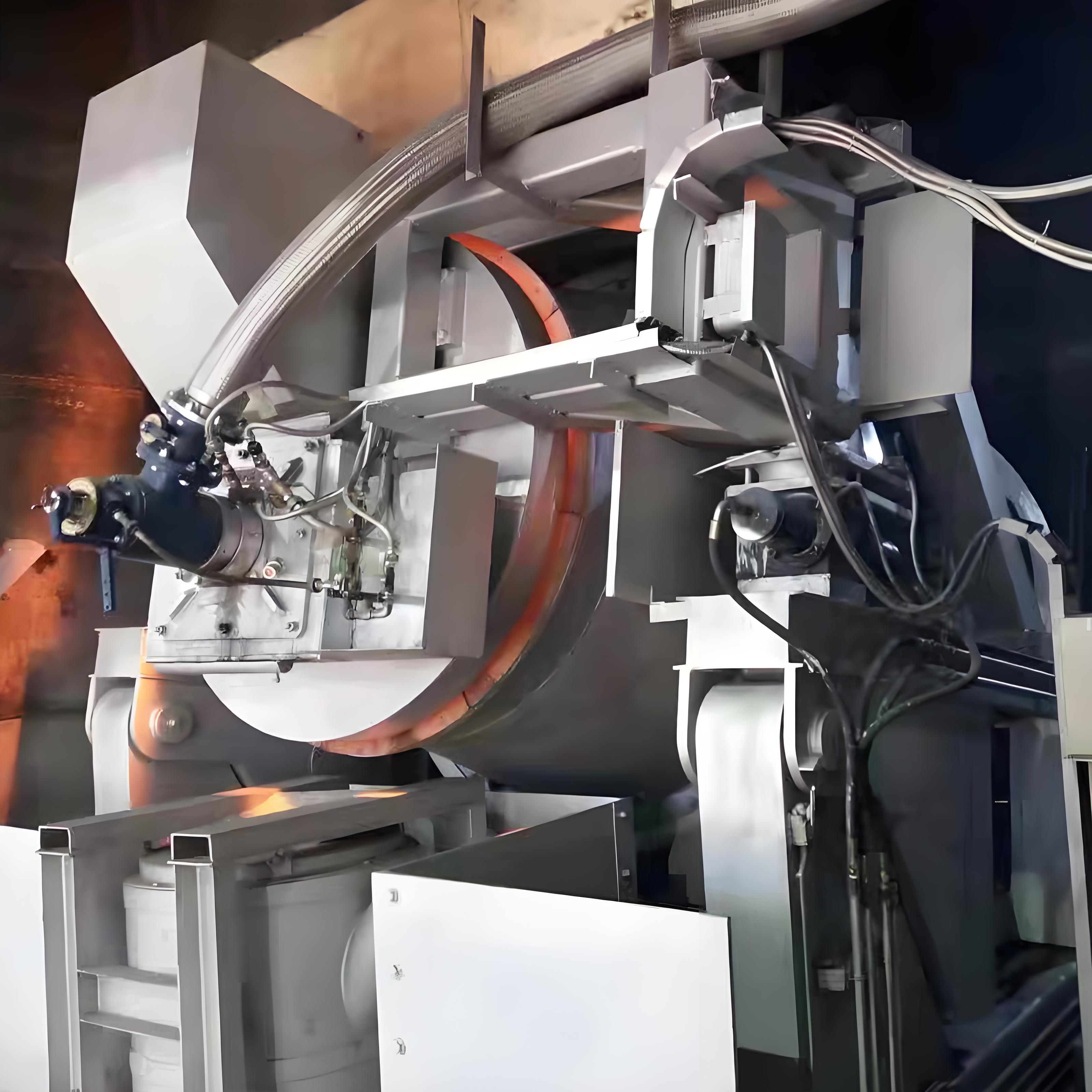

In the complex process chain of antimony smelting, the rotary furnace undoubtedly plays a core role that runs through the entire process. It is far from an independent smelting unit, but a central equipment that integrates material conversion, energy circulation, and process connection. Its importance is reflected in the following three aspects.

Firstly, in terms of core smelting functions, the rotary furnace is responsible for the crucial conversion from antimony concentrate to crude antimony. It efficiently reduces antimony oxide in raw materials to metallic crude antimony through high-temperature reduction melting, completing the most fundamental qualitative change in the entire process and providing the most basic product for all subsequent precision processing. The stability and efficiency of this step directly determine the production capacity and quality cornerstone of the entire production line.

Secondly, in terms of energy supply and circulation, the rotary furnace demonstrates its exquisite design and systematic thinking. While completing its own smelting, the high-temperature flue gas and waste heat generated are not wasted, but cleverly used to provide heat for the preceding rotary kiln. This "energy relay" greatly reduces the system's dependence on external energy, forming an internal energy circulation network, significantly improving the overall thermal efficiency and economy of the process, and is a manifestation of modern green metallurgy concepts.

Finally, in terms of process integration and material flow coordination, the rotary furnace is a key hub that connects the previous and the next. On the one hand, it processes the roasted sand prepared by the rotary kiln; On the other hand, its output is precisely guided to subsequent stages: the crude antimony produced is sent to the refining process for further purification; The flue gas rich in volatile components can be efficiently recovered from high value-added antimony trioxide products through bag dust collection and other treatments; Even the treatment of its slag is closely linked to environmental requirements. It ensures smooth transfer of material flow between processes and maximizes value utilization.

In summary, the rotary furnace, with its irreplaceable smelting core function, innovative energy cycle contribution, and excellent process flow connection ability, has truly achieved a "continuous" approach. It is like the heart of the entire antimony smelting system, driving the efficient and environmentally friendly flow of matter and energy, and is the cornerstone that supports the continuous, stable, and economic operation of the entire process.